描述

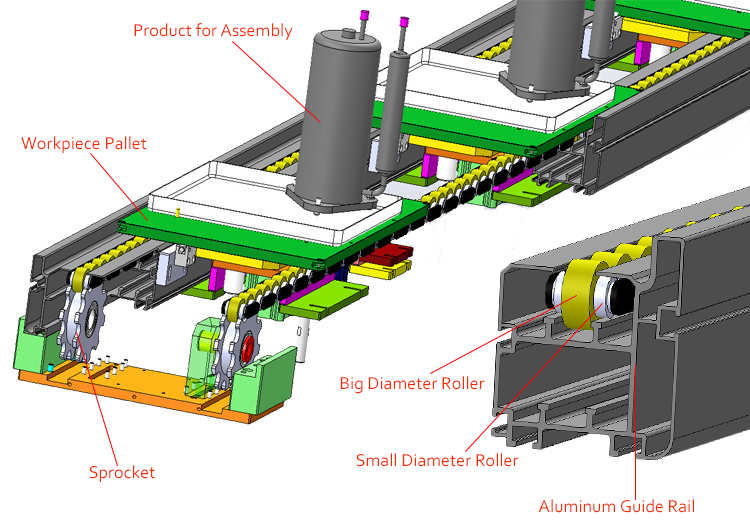

自由流動輸送機 都係即積累軓鏈輸送機或 雙速鏈輸送機. 類似于普通鏈式輸送機, 它#8217也是一台传送机,使用鏈條作為牽引部分同產品. 但也有區別. 輸送原理係利用雙速鏈嘅提速功能. 因此, 支持產品嘅工件托盘可以快速運行. 自由流動鏈輸送機 主要用于裝配生產線. It can realize the complementarity of each work station.

乜嘢係自由流動傳送鏈?

Different from normal chain conveyor, it uses the accumulating roller chain. So what is the difference between them? How does the free flow conveyor chain work?

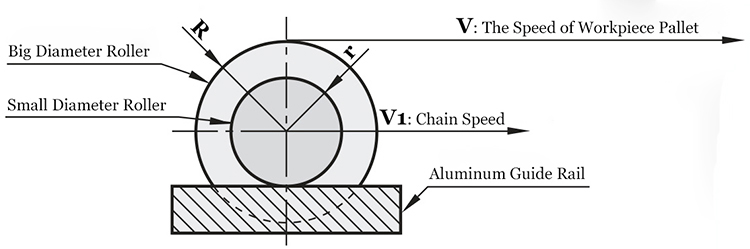

首先, the double-speed chain composes of large-diameter rollers, small-diameter rollers and joint chain links. The small rollers run on the guide rail, and big rollers support the workpiece pallets. When we drag the entire chain to move, it is actually small rollers moving on the guide rail. 另一方面, when the whole chain moves, the large rollers and the small rollers move synchronously. 換句話說, 当細滾筒運行一個圓圈, 大軔都運行一個圓圈. 然而, 由於直徑嘅差異, 佢哋喺水平方向嘅實際運動距離係不同嘅. 大滾筒嘅運行距離比細滾筒大得多.

例如, 自由流動傳送鏈以V1嘅速度運行. 然後細軓嘅周轉速度係V1. 此時, 大軔嘅周轉速度係 (研發)*V1. 因此, 運行速度 (V) 工作托盘係大軔速同鏈速嘅總和. 噉係, V=(研發)*V1+V1=(R/r+1)*V1. 如果大滾筒與小滾筒嘅半徑之比係 1.5:1, 傳送託槃嘅速度為V+(1.5+1)*V1=2.5*V1.

產品嘅運行速度比累積輗鏈快. 因此, 由於雙速鏈嘅特殊結構, 它產生增速效果. 答案係肯定嘅, 由於鏈條結構, 累積滾筒鏈嘅加速速度有限. 自由流動輸送機通常嘅加速效果係V +(2~3)*V1. 常見規格係 2.5 時間速度傳送鏈和 3 時間速度傳送鏈.

點解需要積累滾筒鏈輸送機?

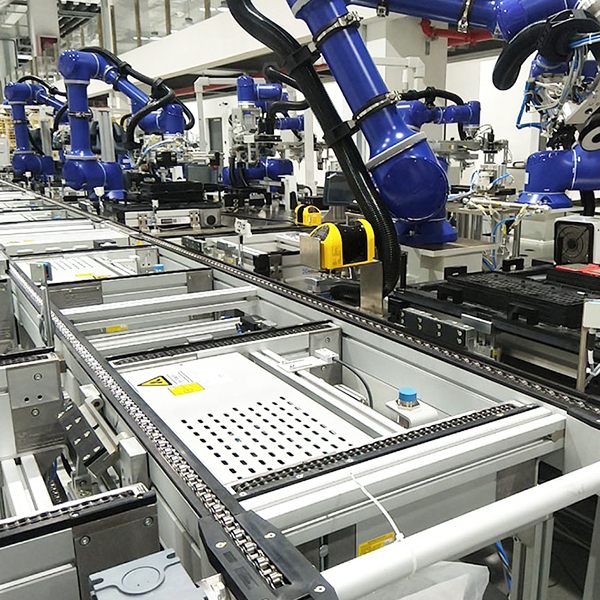

Traditional manual assembly line requires workers on both sides. 例如, there is an air conditioning assembly line. Twist the screws in the first station. The second station installs other parts. The third station is labeled. The efficiency of manual operation is not always very high. To improve production efficiency, we began to use free flow chain conveyor.

The accumulating roller chain can quickly move the pallet from one process to the next. In the double-speed chain conveyor assembly line, each process is operated by robots. In order to facilitate the operation of the robot, it adds blocking mechanisms.

Technical Parameters of Double Speed Chain Conveyor

|

Free flow chain conveyor length |

2000mm~40000mm |

|

工件托盘尺寸 |

160~800mm |

|

托盘裝配輸送機高度 |

根據需要自定義 |

|

最大負載容量 (總) |

200公斤 / 500KG /2000KG |

|

輸送速度 (最大負載) |

20米/分鐘 |

|

輸送機介質 |

08BS / BS25 Accumulating roller chain |

|

框架材料 |

Special Aluminum profile |

|

電機安裝類型 |

結束驅動器或中心驅動器 |

The Characteristic of Accumulating Roller Chain Conveyor

1. 首先, it uses a special aluminum profile as the guide rail. So it makes the double speed chain conveyor have very good stability and durability during the conveying process. 因此, it’s suitable for continuous mass production of products.

2. 其次, it can move the workpiece for long distance. And speed can be fast. 同時, it can realize accumulation type conveying to prevent material backlog.

3. 第三, the conveying capacity is large. 此外, free flow chain conveyor can carry a large load. Loads from 200KG to 2000KG are applicable.

4. It can meet the needs of a variety of production processes, such as glue dispensing, large screws, 焊接, 等.

5. 另外, accumulating roller chain conveyor can achieve a variety of test requirements, such as CCD vision, photoelectric detection, resistance detection, withstand voltage detection, product function detection, 等.

6. Free flow conveyor can be applicable to various types of similar products. 此外, if customers need to increase product types, they can quickly upgrade and transform.

7. The double-speed chain assembly conveyor is flexible. 例如, when we need to improve production efficiency, we can increase the number of pallets and work stations. vice versa. 另一方面, it can also design complex product flow. 例如, we can add horizontal traversing and turning devices to realize a horizontal circular assembly line. Or to achieve a more complex shape of the assembly line.

8. 最後, it can realize intelligent manufacturing functions. The running data, inspection data and production data of the entire production line can be saved and summarized. So it’s convenient to read online or online.

How to choose free flow chain conveyor?

When you need to customize the free flow chain assembly conveyor, please confirm the below details:

1. 首先, it needs to inform the size and weight of the product. Because this will affect the selection of tooling board and motor power.

2. 其次, clarify the shape and layout of the accumulating roller chain conveyor. Is it a straight line, a horizontal loop or a vertical loop?

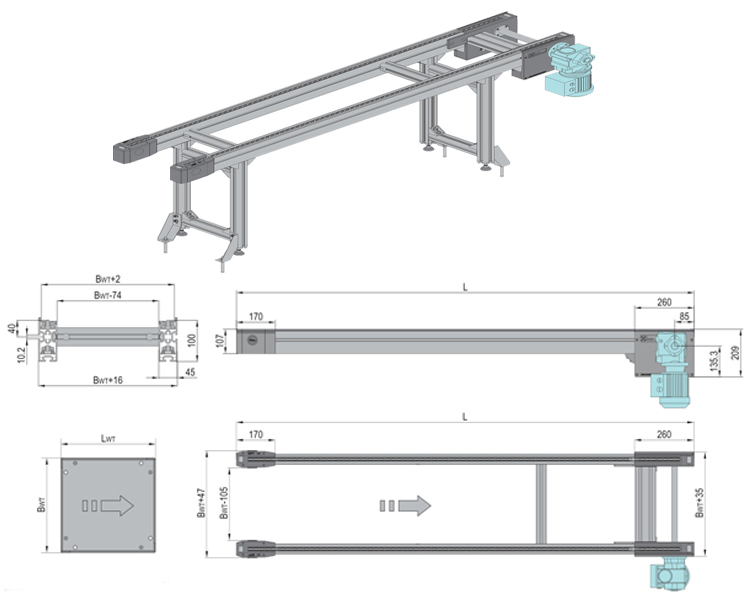

3. 第三, determine the size of the double-speed chain conveyor. The longest can be 30-40 米. The width is generally 250~900mm (定製). 此外, the height is generally 500~1200mm.

4. 第四, confirm the operating speed of the free flow chain conveyor. 麻麻, the maximum speed is 20m/min.

5. 第五, determine the type of double-speed chain. The speed is divided into 2.5 times and 3 次. The large rollers can be stainless steel and engineering plastics.

6. Material selection: there are a variety of materials for workpiece pallets to choose from, such as aluminum, steel, engineering plastic, wood, 等. The frame materials are generally aluminum profiles and painted steel.

7. 另外, it is best to inform your process flow. 同時, inform whether there are additional functions onto free flow conveyor, such as product testing.

8. 最後, confirm the power supply: single-phase 220V / three-phase 380V 50Hz or others.

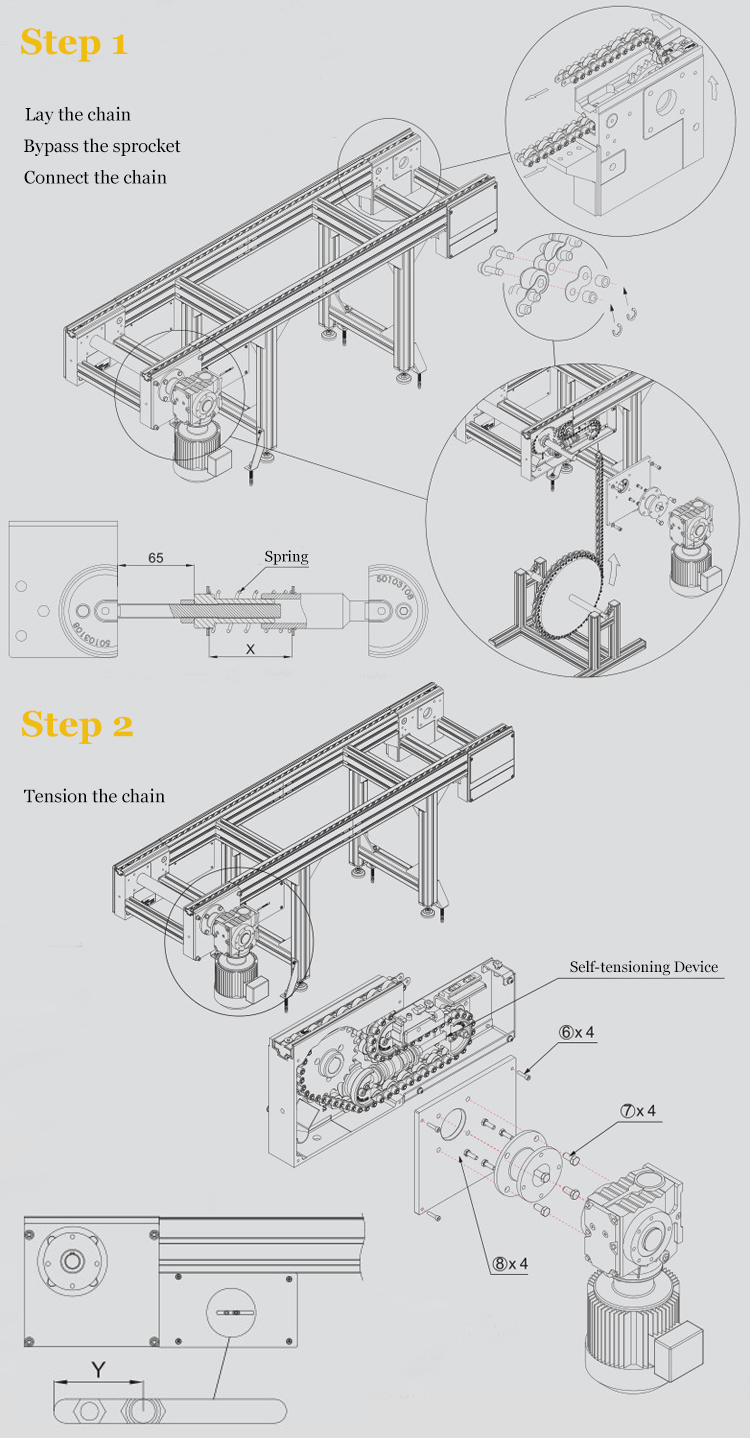

How to replace free flow conveyor chain?

講真, the installation of accumulating rolller chain conveyor is other chain conveyors. When you need to replace the free flow conveyor chain, remove the old chain firstly. 然之後, place the chain on the chain shaft in order to avoid chain damage. And guide the chain trough the lower part of the drive unit. 隨即, bypass driven sprocket, the drive end and the drive sprocket in turn. Finally connect the double speed conveyor chain.

Similar to belt conveyor, free flow conveyor also needs to tighten the chain. Otherwise it will influence the load-bearing capacity of the conveyor assembly line.

親切嘅說明: this free flow chain conveyor has self-tensioning device. It needs often observe the length of Y. 此外, it must ensure that 35≤Y≤55.

How to maintain accumulating roller chain conveyor?

Before starting the free flow chain conveyor daily, we should check whether there are fragments in the chain. 否則, it will damage the chain. 另外, clean the assembly conveyor line each week. And often check if the double speed conveyor chain is loose. 同時, check whether the chain needs lubrication.

Chain lubrication

Before starting the free flow conveyor for the first time, you must lubricate chain. How to lubricate the chain? Drage the whole chain. Lubricate the chain with an amount of about 2~3ml/m. Recommend 15W40 Shell oil.

另外, as long as the equipment is down for more than 6 months, you need re-lubricate it. Before lubricating, remove excess grease, oil stains or other impurities on the accumulating roller chain. 同時, check whether the chain is worn or stretched. Lubrication method and oil volume are the same as above.

During normal use of the assembly conveyor, it needs re-lubricate the chain every 1000 小時. Lubricate a small amount each time-about 2ml/m. 另外, if the operating environment has high humidity, we should shorten the interval time between each lubrication according to the actual situation.

答案係肯定嘅, we can customize the self-lubrication system. It can optimally and uniformly lubricate the free flow conveyor chain during equipment operation.

When using the free flow conveyor, 如果有緊急情況, press the red emergency stop switch immediately. Then turn off the power and start the solution.

評論

未有評論.