描述

裝配線輸送系統係緊要嘅生產線設備. 自由流動橫向輸送機採用雙速鏈作為牽引載躰. 工作託槃可以自由運輸. 它選擇水撥定位, 這樣,工作件可以自由移動或停止. 工作托盘輸送機嘅設計係靈活嘅. 功能都多种多样. 雙速鏈輸送機喺裝配行業具有廣泛嘅應用, 如電子電器和機電行業.

裝配線輸送系統技術規範

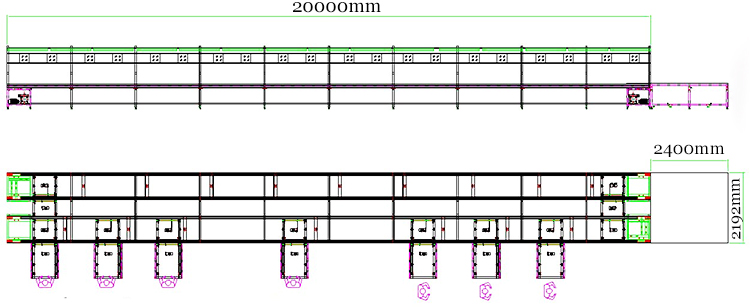

喺呢度,我哋列出咗焊機客戶嘅20米圓形裝配輸送機示例.

| 唔係. | 名字 | 裝配輸送機規格 | Q'ty |

| Circular Assembly Line for Welder | 20 meters(L20m*W1950mm*H1.880m) | 1 set | |

| 1 | 驅動系統 |

|

2 set |

| 2 | 裝配線輸送系統框架 | 1. 支撐支架使用50mm * 50毫米 * 2.毫米方形管; 2. 橫向輸送機超強度100*118mm特殊三速鋁型材嘅導軌; 3. 採用T5 18W單燈罩; 4. 喺每個工作站安裝雙位置插件座椅, 每套1.2米/套; 5. 用20PH快速連接器組裝氣動三胞胎部件40SM; |

40 m |

| 3 | 控制箱 | 使用三菱PLC控制, 三菱空氣掣同欧姆龙繼電器 (其他品牌也有) |

1 set |

| 4 | 工作托盤 | 1. 大小: 升(800)*W(800)*T(20) (毫米); 2. 工作託槃由20毫米木材製成. 另外, 雙層圓形旋轉自由過渡. 此外,表面仲有綠色防靜電橡膠; |

36 個人電腦 |

| 5 | 阻滯劑 | DY-1配備配備腳踏板氣動開關控制嘅高品質阻滯劑; | 34 集 |

| 6 | 工具板嘅提升和轉移設備 | 1. Toho 60W電機驅動同步皮帶輸送; 2. 氣缸配有雙位五向電磁閥,用于提升; 3. 它採用奧姆龍旅行掣. |

11 集 |

| 7 | 過渡轉移設備 | 1. Toho 60W電機驅動同步帶傳送帶; 2. It adopts OMRON travel switch and SKK electric eye. |

2 集 |

| 8 | ESD工作台 | 1000*1000*800毫米 | 7 集 |

| 9 | 試焊機櫃 | 1000*500*1500毫米 | 2 集 |

| 10 | 調試控制櫃 | 550*550*1500毫米 | 7 集 |

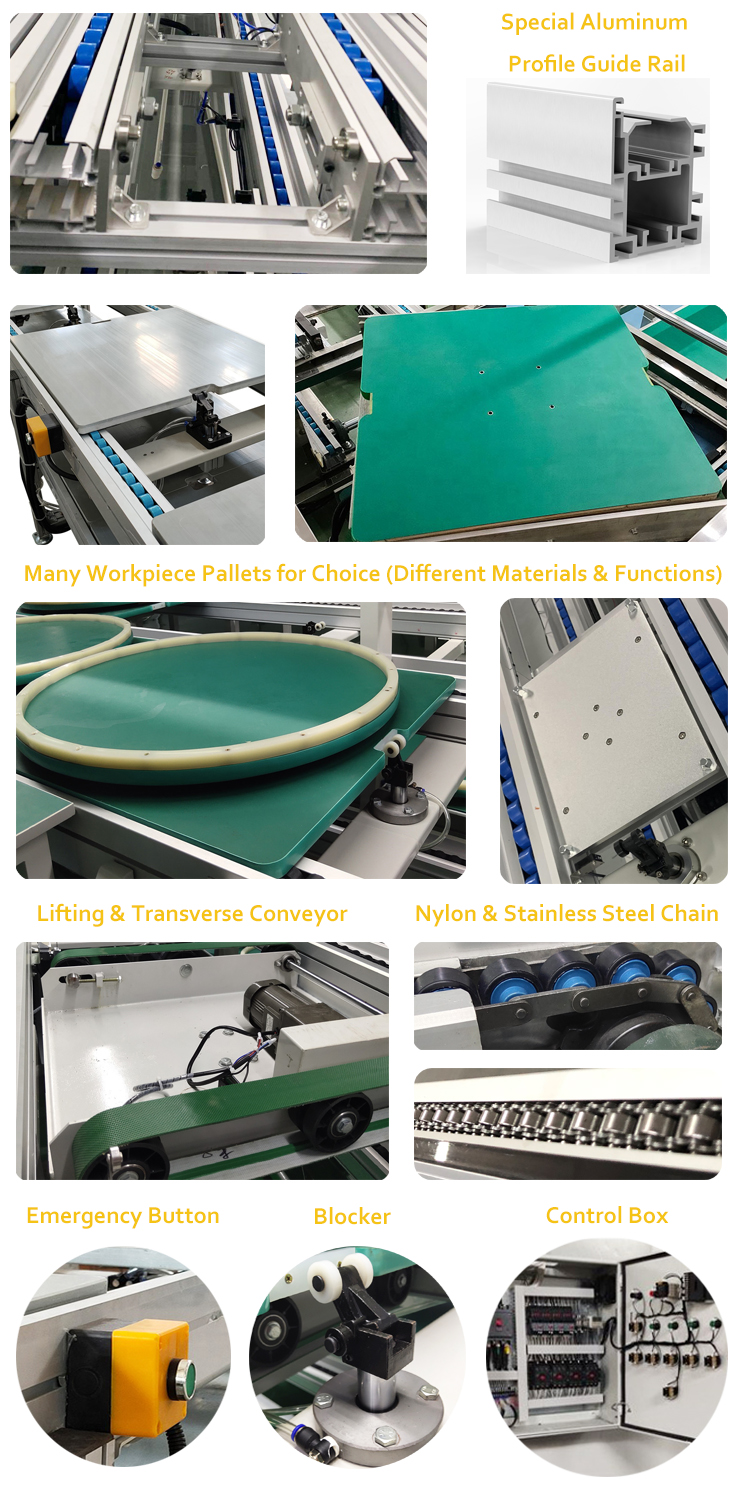

Details & Features of Our Workpiece Pallet Transverse Conveyor

1. 首先, the double-speed chain conveyor uses a special aluminum profile guide rails. It is different from other conveyor rails.

2. 其次, the workpiece pallet can be customizable according to the specific production process. There are different loads and material choices, such as wood, 聚氯乙烯, aluminum, steel, 等.

3. 第三, the lifting and transverse conveyor can help realize the circular assembly line. It is determined by the size of the workpiece pallet. 在正常情況下, a horizontal circular assembly conveyor line requires 4 sets of traverse conveyors.

4. 同樣地, the accumulation roller chain also has a distinction between load and material. There are light load and heavy load free flow conveyor chains. 另外, there are nylon, carbon steel and stainless steel materials.

5. The blocking mechanism can block the tooling board. The product is processed in the relevant process at this workstation. Release after processing.

6. In case of emergencies, press the emergency button firstly. Then check the assembly line conveyor system.

How to operate the free flow chain assembly line conveyor system?

1. 首先, turn on the compressed air switch. After the gas storage tank pressure reaches 5KG, turn on the gas valve switch to inflate the conveyor assembly line.

2. 其次, turn on the power switch on the panel of the electric control box. 此時, the power indicator light is on. The VFD is energized. Adjust the motor speed according to the production cycle requirements. 然之後, twist the selection mode switch. Choose the mode you want to run. 下一個, activate the run switch. Then the assembly line conveyor system will run automatically.

3. 第三, check whether the lifting and transverse conveyor is lowered in place when there is no workpiece pallet. 如果唔係, reset it manually. 噉係, turn on the manual switch of this conveyor. Then press down manually. Finally reset to the automatic switch.

4. 第四, check whether the lifting and transverse conveyor has risen in place when starting up. 如果唔係, follow the same method as above.

5. 例如, the assembly line conveyor is designed for free rhythm. Each station is set to free-release mode according to the production cycle.

6. 最後, the shutdown operation: turn off the socket power supply, turn off the lighting switch, turn off the air source, and turn off the master switch.

If you want to customize the assembly line conveyor system, pls contact us.

評論

未有評論.