Tavsif

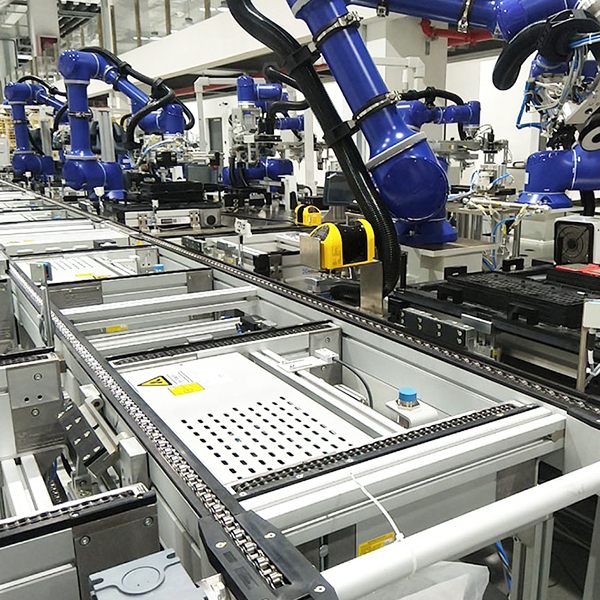

Erkin oqim konveyeri shuningdek, yig'uvchi rolikli zanjirli konveyer yoki ikki tezlikli zanjirli konveyer. Oddiy zanjirli konveyerga o'xshash, bu shuningdek zanjirni tortish qismi va mahsulot sifatida ishlatadigan konveyer mashinasidir. Ammo farq ham bor. Etkazib berish printsipi - ikki tezlikli zanjirning tezlikni oshirish funktsiyasidan foydalanish. Shuning uchun, mahsulotlarni qo'llab-quvvatlaydigan ishlov beriladigan taglik tezda ishlashi mumkin. Erkin oqim zanjirli konveyer asosan yig'ish ishlab chiqarish liniyalarida qo'llaniladi. Bu har bir ish stantsiyasining bir-birini to'ldirishini amalga oshirishi mumkin.

Erkin oqim konveyer zanjiri nima?

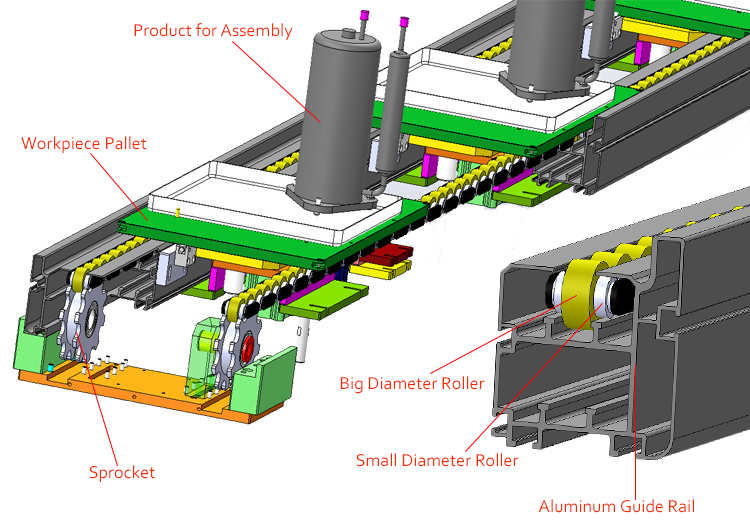

Oddiy zanjirli konveyerdan farq qiladi, u yig'uvchi rolikli zanjirdan foydalanadi. Xo'sh, ularning orasidagi farq nima?? Erkin oqim konveyer zanjiri qanday ishlaydi?

Hammasidan ustun, ikki tezlikli zanjir katta diametrli roliklardan iborat, kichik diametrli rulolar va qo'shma zanjirli bog'ichlar. Kichik tsilindrni yo'naltiruvchi temir yo'lda ishlaydi, va katta tsilindrni ishlov beriladigan palletlarni qo'llab-quvvatlaydi. Biz butun zanjirni harakatga keltirganda, bu aslida yo'riqnomada harakatlanadigan kichik rollarda. Boshqa tarafdan, butun zanjir harakatlanganda, katta valiklar va kichik valiklar sinxron harakat qiladi. Boshqa so'zlar bilan aytganda, kichik rolik bir doira uchun harakat qilganda, katta rolik ham bitta aylana uchun ishlaydi. Ammo, diametrdagi farq tufayli, ularning gorizontal yo'nalishdagi haqiqiy harakat masofasi boshqacha. Katta valikning yugurish masofasi kichik valikka qaraganda ancha katta.

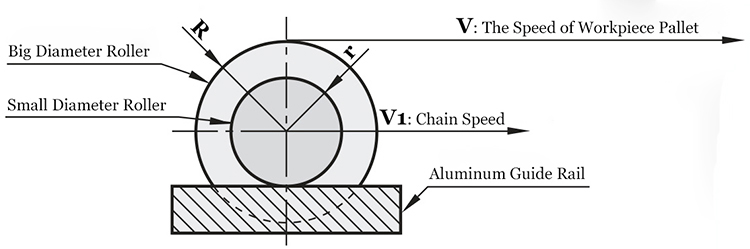

Masalan, erkin oqim konveyer zanjiri V1 tezlikda ishlaydi. Keyin kichik valikning aylanish tezligi V1 ga teng. Shu paytda, katta rolikning aylanish tezligi (R / r)*V1. Shuning uchun, yugurish tezligi (V) ishlov beriladigan palletning katta rolik tezligi va zanjir tezligining yig'indisi. Anavi, V =(R / r)*V1 + V1 =(R / r + 1)*V1. Agar katta valik radiusining kichik valikka nisbati bo'lsa 1.5:1, konveyer palletining tezligi V =(1.5+1)*V1 = 2,5 * V1.

Mahsulotning ishlash tezligi to'plangan rolikli zanjirga qaraganda tezroq. Shuning uchun, ikki tezlikli zanjirning maxsus tuzilishi tufayli, u tezlikni oshiruvchi effekt hosil qiladi. Albatta, zanjir tuzilishi tufayli, yig'uvchi rolikli zanjirning tezligini oshirish cheklangan. Erkin oqim konveyerining odatdagi tezlashuv effekti V =(2~ 3)*V1. Umumiy xususiyatlar 2.5 marta tezlik konveyer zanjiri va 3 tezligi konveyer zanjiri.

Nima uchun rulonli zanjirli konveyerni yig'ish kerak?

An'anaviy qo'lda yig'ish liniyasi har ikki tomonning ishchilarini talab qiladi. Masalan, konditsionerni yig'ish liniyasi mavjud. Birinchi stantsiyadagi vintlarni burab qo'ying. Ikkinchi stantsiya boshqa qismlarni o'rnatadi. Uchinchi stantsiya yorliqlangan. Qo'lda ishlash samaradorligi har doim ham yuqori emas. Ishlab chiqarish samaradorligini oshirish, biz erkin oqim zanjiri konveyeridan foydalanishni boshladik.

The accumulating roller chain can quickly move the pallet from one process to the next. In the double-speed chain conveyor assembly line, each process is operated by robots. In order to facilitate the operation of the robot, it adds blocking mechanisms.

Technical Parameters of Double Speed Chain Conveyor

|

Free flow chain conveyor length |

2000mm~40000mm |

|

Ish qismi sxemasidan o'lchami |

160~ 800 mm |

|

Palet yig'ish konveyerining balandligi |

Ehtiyojlarga ko'ra buyurtma |

|

Maksimal yuk hajmi (jami) |

200KG / 500KG / 2000KG |

|

Tezlikni etkazib berish (maksimal yuk) |

20m / min |

|

Konveyer vositasi |

08BS / BS25 yig'uvchi rolikli zanjir |

|

Asosiy material |

Maxsus alyuminiy profil |

|

Dvigatelni o'rnatish turi |

Oxirgi haydovchi yoki markaziy disk |

G'ildirakli zanjirli konveyerning o'ziga xos xususiyati

1. Birinchidan, u yo'riqnoma sifatida maxsus alyuminiy profildan foydalanadi. Shunday qilib, bu ikki tezlikli zanjirli konveyerni tashish jarayonida juda yaxshi barqarorlik va chidamlilikka ega bo'ladi. Shuning uchun, bu mahsulotlarni doimiy ravishda seriyali ishlab chiqarish uchun javob beradi.

2. Ikkinchidan, u ishlov beriladigan qismni uzoq masofaga ko'chirishi mumkin. Va tezlik tez bo'lishi mumkin. Xuddi shu paytni o'zida, materialning orqada qolishini oldini olish uchun yig'ish turini etkazib berishni amalga oshirishi mumkin.

3. Uchinchidan, the conveying capacity is large. Bundan tashqari, free flow chain conveyor can carry a large load. Loads from 200KG to 2000KG are applicable.

4. It can meet the needs of a variety of production processes, such as glue dispensing, large screws, payvandlash, va boshqalar.

5. Qo'shimcha, accumulating roller chain conveyor can achieve a variety of test requirements, such as CCD vision, photoelectric detection, resistance detection, withstand voltage detection, product function detection, va boshqalar.

6. Free flow conveyor can be applicable to various types of similar products. Bundan tashqari, if customers need to increase product types, they can quickly upgrade and transform.

7. The double-speed chain assembly conveyor is flexible. Masalan, when we need to improve production efficiency, we can increase the number of pallets and work stations. vice versa. Boshqa tarafdan, it can also design complex product flow. Masalan, we can add horizontal traversing and turning devices to realize a horizontal circular assembly line. Or to achieve a more complex shape of the assembly line.

8. Nihoyat, it can realize intelligent manufacturing functions. The running data, butun ishlab chiqarish liniyasining tekshiruv ma'lumotlari va ishlab chiqarish ma'lumotlarini saqlash va umumlashtirish mumkin. Shunday qilib, Internetda yoki Internetda o'qish qulay.

How to choose free flow chain conveyor?

When you need to customize the free flow chain assembly conveyor, please confirm the below details:

1. Birinchidan, it needs to inform the size and weight of the product. Because this will affect the selection of tooling board and motor power.

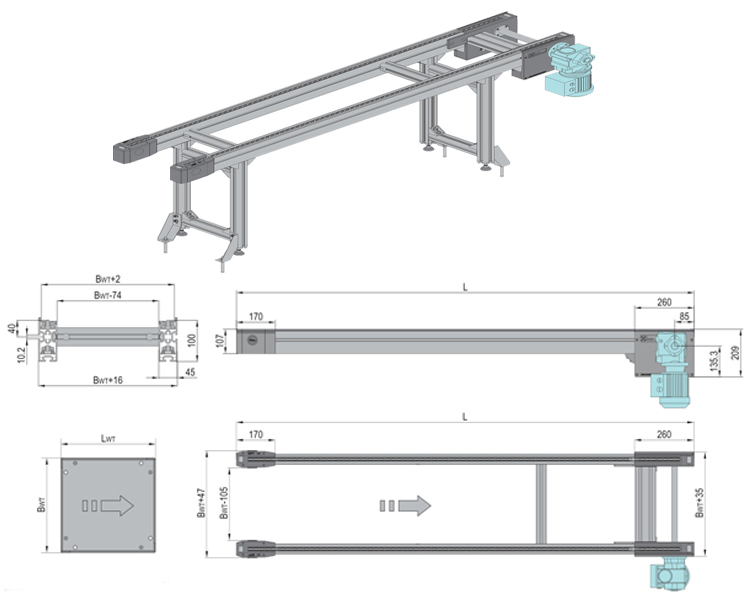

2. Ikkinchidan, clarify the shape and layout of the accumulating roller chain conveyor. Is it a straight line, a horizontal loop or a vertical loop?

3. Uchinchidan, determine the size of the double-speed chain conveyor. The longest can be 30-40 metr. The width is generally 250~900mm (sozlash mumkin). Qo'shimcha, the height is generally 500~1200mm.

4. To'rtinchidan, confirm the operating speed of the free flow chain conveyor. Odatda, the maximum speed is 20m/min.

5. Beshinchidan, determine the type of double-speed chain. The speed is divided into 2.5 times and 3 marta. The large rollers can be stainless steel and engineering plastics.

6. Material selection: there are a variety of materials for workpiece pallets to choose from, such as aluminum, po'lat, engineering plastic, wood, va boshqalar. The frame materials are generally aluminum profiles and painted steel.

7. Qo'shimcha, it is best to inform your process flow. Xuddi shu paytni o'zida, inform whether there are additional functions onto free flow conveyor, such as product testing.

8. Nihoyat, confirm the power supply: single-phase 220V / three-phase 380V 50Hz or others.

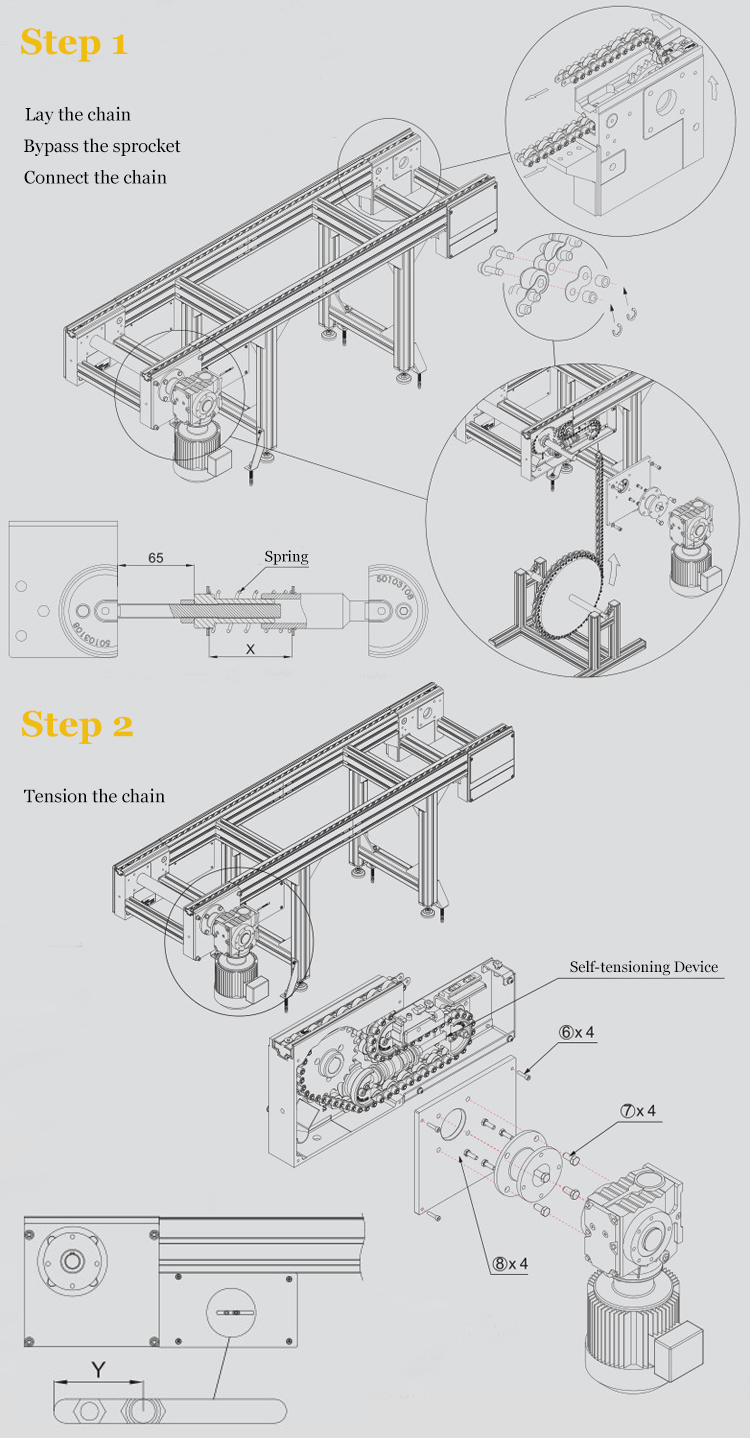

How to replace free flow conveyor chain?

Aslida, the installation of accumulating rolller chain conveyor is other chain conveyors. When you need to replace the free flow conveyor chain, remove the old chain firstly. Keyin, place the chain on the chain shaft in order to avoid chain damage. And guide the chain trough the lower part of the drive unit. Darhol keyin, bypass driven sprocket, the drive end and the drive sprocket in turn. Finally connect the double speed conveyor chain.

Similar to belt conveyor, free flow conveyor also needs to tighten the chain. Otherwise it will influence the load-bearing capacity of the conveyor assembly line.

Yaxshi eslatma: this free flow chain conveyor has self-tensioning device. It needs often observe the length of Y. Bundan tashqari, it must ensure that 35≤Y≤55.

How to maintain accumulating roller chain conveyor?

Before starting the free flow chain conveyor daily, we should check whether there are fragments in the chain. Aks holda, it will damage the chain. Qo'shimcha, clean the assembly conveyor line each week. And often check if the double speed conveyor chain is loose. Xuddi shu paytni o'zida, check whether the chain needs lubrication.

Chain lubrication

Before starting the free flow conveyor for the first time, you must lubricate chain. How to lubricate the chain? Drage the whole chain. Lubricate the chain with an amount of about 2~3ml/m. Recommend 15W40 Shell oil.

Qo'shimcha, as long as the equipment is down for more than 6 months, you need re-lubricate it. Before lubricating, remove excess grease, oil stains or other impurities on the accumulating roller chain. Xuddi shu paytni o'zida, check whether the chain is worn or stretched. Lubrication method and oil volume are the same as above.

During normal use of the assembly conveyor, it needs re-lubricate the chain every 1000 soat. Lubricate a small amount each time-about 2ml/m. Qo'shimcha, if the operating environment has high humidity, we should shorten the interval time between each lubrication according to the actual situation.

Albatta, we can customize the self-lubrication system. It can optimally and uniformly lubricate the free flow conveyor chain during equipment operation.

When using the free flow conveyor, Quritish haroratini to'g'ridan-to'g'ri kompyuterga kiriting, press the red emergency stop switch immediately. Then turn off the power and start the solution.

Sharhlar

Hozircha hech qanday sharh yo'q.