8 Kinds of Truck Loading Unloading Conveyor System

Modern logistics is developing rapidly. At the same time, labor costs also continue to increase. So we need truck loading unloading conveyor to reduce the amount of labor. And BCC CONVEYOR can customize 8 types of truck loading and unloading conveyor. Most of brick loading conveyors are portable and telescopic. They are also suitable for brick, container, train, railcar, wagon, vessel, etc. Next, we will introduce these 8 kinds of telescopic conveyors for truck loading separately.

1. liftable truck loading unloading conveyor.

Above all, it is a incline belt conveyor. Its loading and unloading is safe and efficient. The biggest advantage is to provide ergonomic operating conditions. Because the operator can control the expansion and contraction of the conveyor through buttons and joysticks. Therefore, it can adjust the conveyor easily and effectively. So it shortens the loading and unloading time. At the same time, reduce damage and failure rate. Below are the advantages & features of this loading belt conveyor:

(1) The conveyor is freely expandable in the length direction;

(2) It can run forwards and backwards. Therefore, it can easily complete the two functions of loading and unloading;

(3) The telescopic conveyor part and the belt conveyor part can be combined or used separately.

(4) You can adjust the height of conveyor equipment arbitrarily according to the height of the truck.

(5) According to the cargo volume and manpower, set the appropriate conveying speed. This makes the loading and unloading work faster and labor-saving.

(6) The front-end conveyor is always in a horizontal working state. Therefore, it is convenient for personnel to take the goods, saving time and effort.

(7) Because of wheels, it is very convenient to move and operate. Especially in the environment where there is no loading and unloading platform, it is more convenient and fast.

(8) The incline conveyor and the horizontal conveyor form a whole machine. So it reduces labor intensity.

(9) The front-end suspension flexible conveyor can be stretched arbitrarily. So make unloading more convenient.

(10) It’s suitable for various forms of packaging, such as carton, woven bag, plastic box, etc.

Because of the above advantages, this truck loading unloading conveyor has wide application in the fields of goods in and out of warehouses, vehicle loading and unloading, and automated conveying systems.

2. Telescopic Belt Conveyor

Secondly, this conveyor can also act as brick loading conveyor. The telescopic belt conveyor adds a telescopic mechanism to the ordinary belt conveyor. Therefore, the belt conveyor can be freely stretched in the length direction. Users can adjust the buttons according to their requirements to control the length of the conveyor at any time. If with automatic lifting devices, users can also control the height of the end of the conveyor at any time. Telescopic belt conveyors are mainly used in vehicle loading and unloading and material transfer systems.

This telescopic truck loading and unloading conveyor has several models: two-stage, three-stage and four-stage. The width of the conveyor belt: 500, 600, 700, 800, 1000, 1200mm. In addition, the conveyor speed of the telescopic belt can be fixed speed or variable speed. And conveying direction can be one-way or two-way conveying. Belt conveyor inclination can be horizontal, fixed inclination or automatic lifting. The base of this telescopic loading conveyor can be fixed or mobile. Conveying speed: <30m/min. Below are the features of this brick loading conveyor:

(1) Easy work: Reduce manual round-trip transportation and reduce labor intensity.

(2) Efficient operation: Calculated at the standard loading speed of 30m/min. The theoretical maximum loading capacity of cartons (800*600mm) per hour is 2250 pieces.

(3) Standard operations: standard procedures for loading and warehousing sites. Therefore, it effectively avoids the messy site and the phenomenon of working all over the floor.

(4) Labor saving: it can reduce the number of labor for loading to more than 1/3 of the original. Therefore, cost savings.

(5) Safe operation: it can reduce the accident rate during the loading process to a minimum, or even zero.

(6) Enhance corporate image: standard automation equipment streamline operation. Therefore, this truck loading unloading conveyor meets the requirements of modern enterprises.

3. Foldable Incline Belt Conveyor

This kind of belt loading unloading conveyor is different from other types. Compared to other conveyors, it is not expandable, but foldable. Moreover, it has larger load-bearing capacity. The whole load capacity can reach 500KG. In addition, the belt uses the 8.0mm thickness anti-slip rubber belt. Besides, its application range is wider. You can use it not only to transport boxes and bags, but also to transport bulk goods, such as grain, gravel, garbage, etc. You can choose to add the cleat and side guard plates. Additionally, it can also add a hopper.

(1) This portable belt conveyors is especially suitable for places where loading and unloading locations are frequently changed.

(2)Because of the universal wheels at the bottom of the conveyor, you can move it at will according to the stacking position of the material.

(3)The lifting method can be electric lifting or manual lifting.

(4)Loading conveyor belt can be foldable. So it takes up little space. Besides, you can put it on your truck. So you can carry it anywhere.

(5)The belt adopts non-slip design. Moreover, the rubber belt is more wear-resistant.

(6)Two-way transportation design. So it is suitable for both loading and unloading.

(7)The width and length of this truck loading and unloading can be customizable.

4. Flexible Roller Conveyor

There are two types of flexible conveyor, namely flexible roller conveyor and skate wheel conveyor. Among them, the flexible roller conveyor also has two types, that is to say, unpower and powered conveyor. Generally speaking, the load capacity of the these two expandable flex conveyors is not large. They are suitable for conveying all kinds of boxes, bags, pallets, etc.

The max load-bearing weight of flexible roller conveyor is 80~100KG. Of course, different structures, different loading capacity. Generally, flexible roller conveyor with motor can acts as truck loading unloading conveyor. But if without motor, it can only act as unloading conveyor. Below are the features of this brick loading unloading conveyor.

(1) The conveyor can freely change direction and change any angle. Besides it can form straight section and circular arc section according to need. Therefore, the layout is flexible.

(2) The height of the stands can be adjustable. Moreover, because of casters, it is able to move. At the same time, the casters are with brakes. The extension length can be limited.

(3) Wide range of advantages: low cost, simple structure, convenient maintenance, reliable operation, and strong conveying capacity.

(4) Because it can expand freely, it occupies a small area. The expansion ratio is almost 2.5~3:1.

(5) In addition, you can use the flexible rolle seperately. Or it can also be combined with other conveying equipment to realize the transfer of goods.

(6) This flexible truck loading unloading has wide applications in material handling and sorting.

5. Skate Wheel Conveyor

It is one kind of flexible expandable conveyors. Different from the conveyor above, skate wheel conveyor can not act as truck loading conveyor. Besides, its load capacity is usually not high. It is suitable for conveying goods with a flat bottom. Convenient and efficient transportation and unloading. Below are its technical specifications:

(1) Length: custom according to needs.

(2) Optional width: 500mm, 600mm, 800mm.

(3) Height adjustable: 450-650mm/500-800mm/750-1100mm/950-1600mm/1300-2000mm, also can be customized in mm.

(4) Conveying speed: 1-20m/min.

(5) Load capacity: 30kg/unit.

(6) Skate wheel: plastic steel/carbon steel.

(7) Telescopic piece: thickened flexible piece: 3.0mm, wear-resistant and durable.

(8) Conveyor frame: carbon steel/stainless steel.

(9) The surface of tie rods and legs are galvanized, wear-resistant and corrosion-resistant.

(10) The expansion ratio of this truck unloading conveyor is 2.5~3:1.

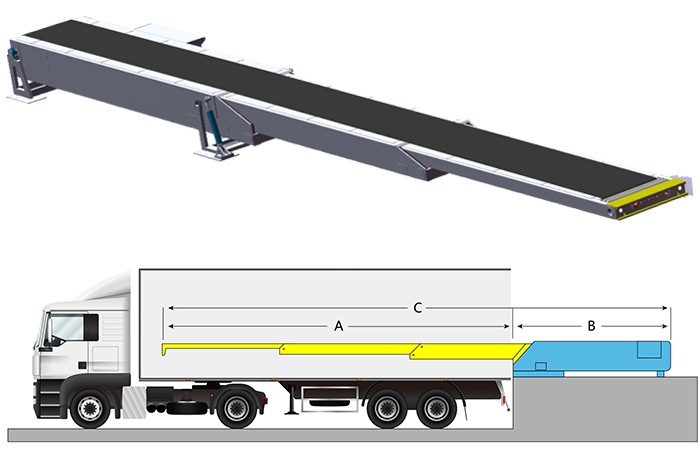

6. Telescopic Conveyor for Truck UnLoading

In fact, this is a combination of conveyor equipments. It comproses of telescopic conveyor and roller conveyor. Among them, the telescopic conveyor can be telescopic belt conveyor or telescopic roller conveyor. This conveyor can only act as truck unloading conveyor, not loading conveyor.

- It is expandable. So easy to use. Small footprint.

- You can use it together with other flexible conveyors. Therefore, it can adapt to different requirements.

- Equipped with wheels for easy movement.

- Generally applicable for the transportation of boxes and bags.

7. Foldable Roller Conveyor without Stands

This is no power roller conveyor. Different from other roller conveyors, it is foldable. Besides, it has no stands. Of course, it can only act as truck unloading conveyor, not loading conveyor. The roller material can be stainless steel or galvanized rollers. And the frame can be painted steel, aluminum alloy or stainless steel.

Its characteristics and advantages are as follows:

(1) The length and width can be customizable.

(2) Several conveyors can be combined and used together.

(3) Lightweight, convenient and easy to carry. At the same time it’s foldable. So it doesn’t occupy large area.

(4) Compared with the above truck loading unloading conveyors, its price is cheaper.

8. Sliding Roller Track

It is similar to the 7th conveyor. You can also connect several sets to use together. It is very lightweight. Simple to use.. And its load capacity is not high. Moreover, you can only use it for unloading. And the roller material can be plastic or aluminum alloy.

If you need to buy track loading unloading conveyor, please contact us.