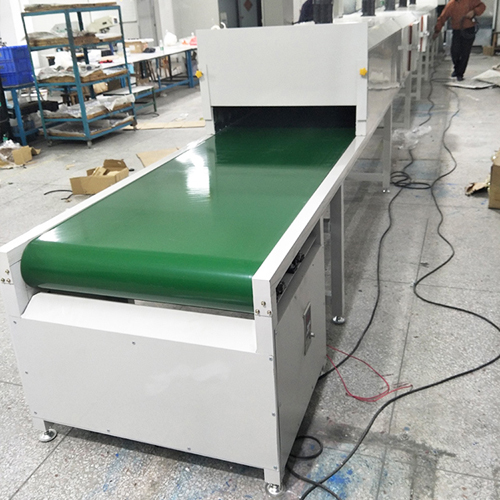

Paglalarawan

Ang belt conveyor oven na ito ay mayroon 10 haba ng metro at 5 mga sona ng pag-init. Ito ay isang mababang temperatura pang-industriya na conveyor dryer. At pinagtibay nito ang berdeng PVC belt upang maihatid ang mga kalakal. Ang maximum na temperatura ng sinturon ng PVC ay 80 ° C. Kaya karaniwang ginagamit namin ang drying drying oven na ito upang maiinit & gamutin ang tinta at pandikit para sa electronics, pagpi-print ng screen, plastik & goma & pagpipinta ng silicone, atbp.

Ang prinsipyo ng pagtatrabaho ng patuloy na oven ng conveyor ng sinturon

Una, ang mga infrared heaters ay gumagana at ang mga tagahanga ng impeller ay kumalat ang init sa mga zone ng pag-init. Pagkatapos ng preheat, ang pang-industriya na conveyor dryer ay nagpainit hanggang sa itinakdang temperatura. Pagkatapos ay ihatid ng sinturon ng PVC ang mga produkto sa mga drying zone. Ginagawa ng mainit na sirkulasyon ng hangin ang temperatura sa pare-pareho ng drying drying oven. Ito ay isang mahalagang tagapagpahiwatig upang matiyak ang kalidad ng mga patong ng produkto.

Iba't ibang mga zone ng pag-init, iba't ibang mga sistema ng pagkontrol sa temperatura. Kaya't maaari nitong madaling matugunan ang mga kinakailangan ng proseso ng produksyon. Dahil sa RKC termostat, ang belt conveyor oven ay maaaring tumpak na makontrol ang temperatura.

Mga pagtutukoy ng conveyor drying oven

1. The stands of belt conveyor oven are 40*40mm square tubes with adjustable feet.

2. Conveyor belt: PVC belt, width 600mm, belt thickness 2.0mm.

3. Power part: 1.5KW three-phase motor, with frequency conversion speed regulation (0~6 meters per minute adjustable).

4. The outer cover of conveyor drying oven is made of cold plates. Effective dimensions of the inner zone: lapad 600 mm, height 50 mm.

5. The inner liner materials are galvanized sheet. The entrance and exit height is 100mm (napapasadyang).

6. The use of aluminum silicate cotton has good thermal insulation effect.

7. The heating elements use the infrared quartz heater tube with a power of 1KW.

8. Each cover of industrial conveyor dryer can be raised independently for easy maintenance.

9. Tunnel oven color: computer white (napapasadyang).

Features of industrial tunnel drying oven

1. Una, conveyor drying oven can achieve sectional control (when rising to set temperature, you can turn off several sections of the heating tubes at will to reduce the heating power. So it can save the power);

2. Pangalawa, the belt conveyor oven adopts intelligent temperature controller. At the same time, with SSR solid-state relay output, it can precisely control the accuracy of temperature. At saka, there is an over-temperature protection function. Samakatuwid, when reaching the set temperature, it will automatically stop heating.

3. Pangatlo, simple operation, convenient maintenance and adjustment. Low noise and high reliability. Low cost, low energy consumption and high production efficiency.

4. Sa wakas, this industrial conveyor dryer is with exhaust pipe. Tunnel oven are often used for drying and curing SMT components, printed circuit boards, electronic products, atbp. So it can discharge the exhaust gas generated during the drying process.

FAQ

Q1: How long is the service life of the heating tube?

A1: For our belt conveyor oven, the service life time of heater can be up to 2~3 years.

Q2: What kind of heating element does your conveyor drying oven use?

A2: Usually, our continuous drying oven uses the infrared heating lamps. Syempre, we can also supply the stainless steel heater or heater with heat sink.

Q3: What brand of thermostat does your tunnel dryer use?

A3: Our industrial conveyor dryer usually adopts the RKC brand thermostat.

Q4: What about the warranty time of your conveyor belt dryer?

A4: The warranty time of our belt conveyor oven ay isang taon.

Mga pagsusuri

Wala pang mga review.