Descriere

Sistemul de transport pe linia de asamblare este un echipament important pentru linia de producție. Transportorul transversal cu flux liber adoptă lanțul cu dublă viteză ca suport de tracțiune. Paletul piesei de prelucrat se poate transporta liber. Selectează poziționarea dopului, astfel încât piesa de prelucrat să se poată mișca sau opri liber. Proiectarea transportorului de paleți pentru piese este flexibilă. Iar funcțiile sunt diverse. Transportorul cu lanț cu dublă viteză are aplicații largi pentru industriile de asamblare, precum aparatele electronice și industriile electromecanice.

Specificații tehnice ale sistemului de transport pe linia de asamblare

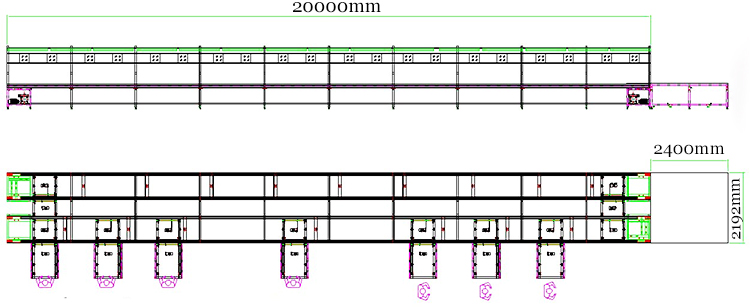

Here we list an example of a 20m circular assembly conveyor for a welder machine customer.

| Nu. | Nume | Assembly Conveyor Specification | Q’ty |

| Circular Assembly Line for Welder | 20 meters(L20m*W1950mm*H1.880m) | 1 set | |

| 1 | Sistem de acționare |

|

2 set |

| 2 | Frame of Assembly Line Conveyor System | 1. The support stands use 50mm * 50mm * 2.mm square tubes; 2. The guide rails of transverse conveyor super-strength 100*118mm special triple-speed aluminum profiles; 3. It adopts T5 18W single LED lamp with cover; 4. Install two-position plug-in seats at each workstation, each 1.2m/set; 5. Assemble the pneumatic triplet parts 40SM with 20PH quick connector; |

40 m |

| 3 | Control Box | Using Mitsubishi PLC control, Mitsubishi air switch and OMRON relay (Other brands are available) |

1 set |

| 4 | Workpiece Pallet | 1. mărimea: L(800)*W(800)*oar Structura(20) (mm); 2. The workpiece pallet is made of 20mm wood. în plus, double-layer circular rotation free transition. Besides there is green anti-static rubber on the surface; |

36 buc |

| 5 | Blocker | DY-1 high-quality blocker equipped with foot pedal pneumatic switch control; | 34 seturi |

| 6 | Lifting and Transferring Device for Tooling Board | 1. Toho 60W motor drives synchronous belt conveying; 2. The cylinder is with two-position five-way solenoid valve for lifting; 3. It adopts OMRON travel switch. |

11 seturi |

| 7 | Transitional Transfer Device | 1. Toho 60W motor-driven synchronous belt conveyor; 2. It adopts OMRON travel switch and SKK electric eye. |

2 seturi |

| 8 | ESD Workbench | 1000*1000*800mm | 7 seturi |

| 9 | Trial Welding Cabinet | 1000*500*1500mm | 2 seturi |

| 10 | Commissioning Control Cabinet | 550*550*1500mm | 7 seturi |

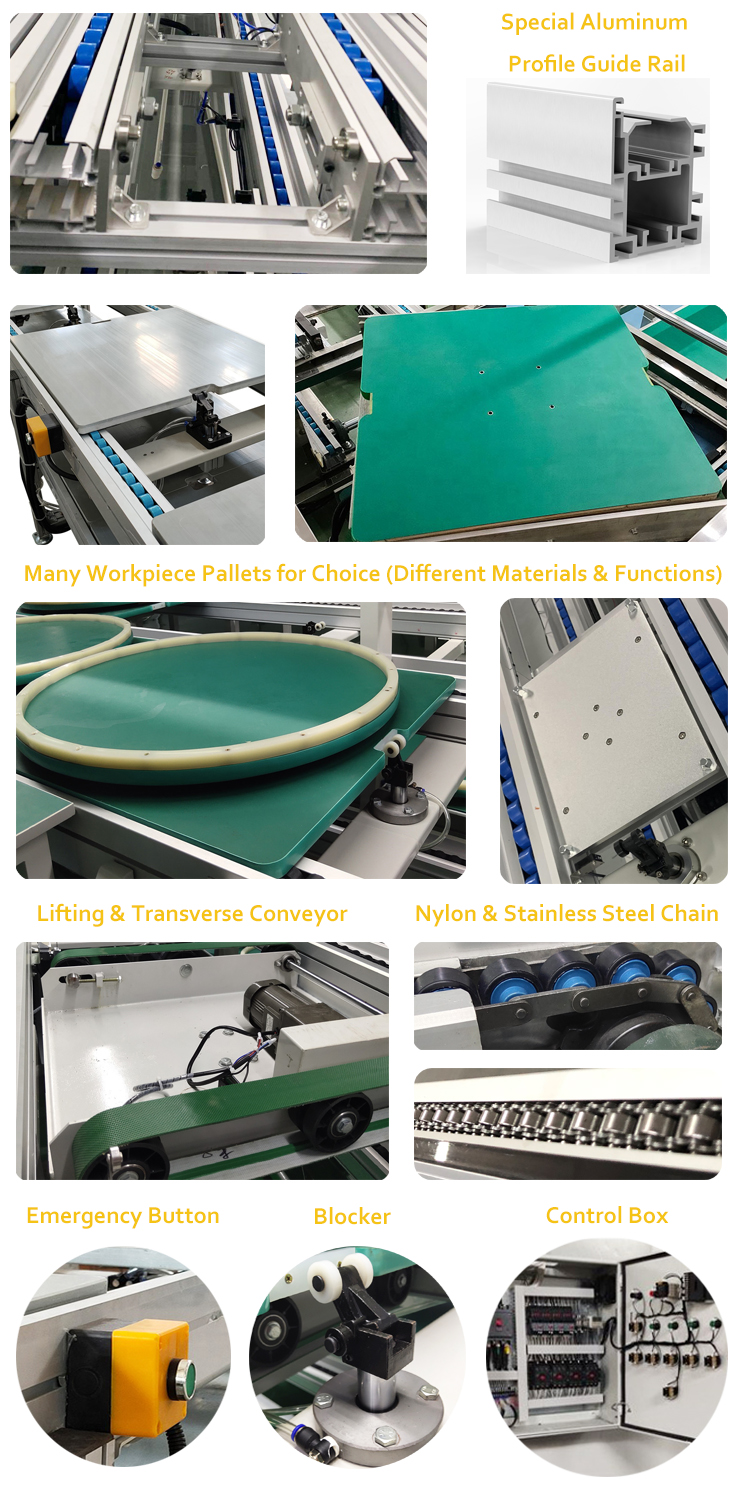

Details & Features of Our Workpiece Pallet Transverse Conveyor

1. in primul rand, the double-speed chain conveyor uses a special aluminum profile guide rails. It is different from other conveyor rails.

2. În al doilea rând, the workpiece pallet can be customizable according to the specific production process. There are different loads and material choices, such as wood, PVC, aluminiu, oţel, etc.

3. În al treilea rând, the lifting and transverse conveyor can help realize the circular assembly line. It is determined by the size of the workpiece pallet. sub circumstante normale, a horizontal circular assembly conveyor line requires 4 sets of traverse conveyors.

4. În mod similar, the accumulation roller chain also has a distinction between load and material. There are light load and heavy load free flow conveyor chains. în plus, there are nylon, carbon steel and stainless steel materials.

5. The blocking mechanism can block the tooling board. The product is processed in the relevant process at this workstation. Release after processing.

6. In case of emergencies, press the emergency button firstly. Then check the assembly line conveyor system.

How to operate the free flow chain assembly line conveyor system?

1. in primul rand, turn on the compressed air switch. After the gas storage tank pressure reaches 5KG, turn on the gas valve switch to inflate the conveyor assembly line.

2. În al doilea rând, turn on the power switch on the panel of the electric control box. Momentan, indicatorul luminos de alimentare este aprins. The VFD is energized. Adjust the motor speed according to the production cycle requirements. Apoi, twist the selection mode switch. Choose the mode you want to run. Următorul, activate the run switch. Then the assembly line conveyor system will run automatically.

3. În al treilea rând, check whether the lifting and transverse conveyor is lowered in place when there is no workpiece pallet. Dacă nu, reset it manually. Acesta este, turn on the manual switch of this conveyor. Then press down manually. Finally reset to the automatic switch.

4. În al patrulea rând, check whether the lifting and transverse conveyor has risen in place when starting up. Dacă nu, follow the same method as above.

5. De exemplu, the assembly line conveyor is designed for free rhythm. Each station is set to free-release mode according to the production cycle.

6. In cele din urma, the shutdown operation: turn off the socket power supply, turn off the lighting switch, turn off the air source, and turn off the master switch.

If you want to customize the sistem de transport pe linia de asamblare, pls contact us.

opinii

Nu există comentarii încă.