Penerangan

Ini adalah ketuhar roller conveyor untuk pelanggan Perancis kami. Ia adalah ketuhar penghantar inframerah suhu tinggi untuk memasak serpihan plastik. Suhu kerja ialah 250 ℃ dan suhu maksimum. ialah 300 ℃. Pelanggan meletakkan serpihan plastik ke dalam dulang keluli, dan kemudian masukkan dulang ke roller conveyor untuk rawatan haba. Kerana suhu tinggi, kami guna 304 penggelek keluli tahan karat. Sebagai tambahan, ketuhar terowong industri berterusan ini merangkumi tiga bahagian. Iaitu, penghantar masuk, penghantar keluar dan relau terowong tengah.

Relau pengeringan menggunakan peredaran udara panas + kaedah pemanasan IR jauh. Suhu seragam di ketuhar terowong industri. Besides temperature rises quickly. Infrared conveyor oven has wide application in many industries, such as hardware metal parts, plastik, percetakan skrin, powder coating, PCB or electronics, dan lain-lain. The conveyor furnace can play the role of drying and curing. Sebagai tambahan, conveyor oven can also suitable for food industry, such as pizza, biskut, bread and seafood. It can play a role in drying, dehydrating and sterilizing.

How does infrared conveyor oven work?

The industrial tunnel oven is a tunnel type machine that drying products through heat conduction, convection, and radiation. There is a continuous conveyor system in the tunnel. It will generate the relative movement between the product and the heating element through the conveyor chain, roller or mesh belt. So as to complete the work of uniform baking and conveying.

There are several types of heating elements, such as infrared heating tubes, stainless steel heating tubes and so on. Infrared rays can reach every corner of the furnace. Then the temperature rises evenly, transferring energy to the object. Pada masa yang sama, the wind motor drives the blades to generate hot air circulation. Oleh itu, the upper and lower temperatures in the furnace are more uniform. So as to ensure the quality of oven products. Sebagai tambahan, the thermal insulation material has good thermal insulation performance and can effectively prevent heat loss.

Industrial Tunnel Oven Technical Data

What is a tunnel oven made of? The conveyor furnace mainly includes several parts, such as conveyor, insulation & sistem pemanasan, control system and safety protection system.

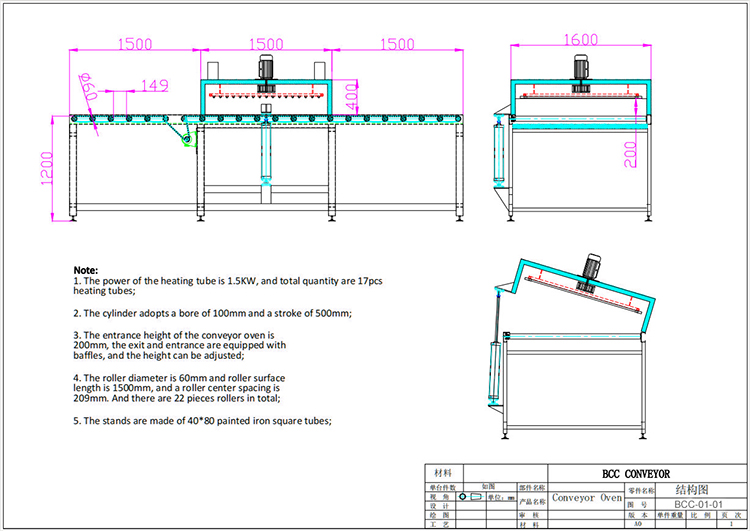

The following are the technical specifications of the roller conveyor tunnel furnace for our French customer.

Total length is 4.5m and conveying surface width is 1.4m. Selain itu, the working temperature is 250℃ for 30 minit.

1. Pertama, the oven shell uses 1.5 thickness galvanized sheet.

2. Kedua, the inner liner uses 1.5 thickness 304 stainless steel mirror panels. And weld well all around in order to prevent high temperature cracking.

3. Ketiga, use two layers of 40mm thickness aluminum silicate as insulation material.

4. Keempat, Taiwan brand high-quality infrared heating tube: 17pcs, and each power is 1.5KW. So the power of industrial tunnel oven is about 25KW.

5. Kelima, 750W Wind-driving motor, with 12-inch pig-cage fan blades.

6. Install the air baffles on the left and right sides. When infrared conveyor oven heats up, close them manually. Then the tunnel oven starts to work. Selain itu, disana ada 2 air outlets on the top.

7. Keenam, control electric box:

Chint brand. With leakage protection air switch, start switch, indicator light. With digital display thermometer, Chint AC contactor, independent control box for drying furnace.

The temperature range is from room temperature to 300℃. Timing control. Alarm function. Set automatic temperature control. And use the RKC thermostat.

8. Sebagai tambahan, there is cylinders to lift the oven cover for maintenance.

10. Appearance color: powder spraying, and color is deep-gray as request.

11. The side guide rails of the roller conveyor are bent into a C shape with a 3mm thickness cold rolled plate.

12. The support stands use 40*80 2.0mm thick square steel tube. Selain itu, they are with M14 adjusting foot (height-adjustable from 1200 to 1300mm).

13. Selanjutnya, kami guna 304 penggelek keluli tahan karat. Double-row gears. Ketebalan roller adalah 2mm. Diameter ialah 60mm. Dan jarak roller ialah 150mm.

14. Akhirnya, roller conveyor menggunakan motor 750W jenama AQL. Nisbah kelajuan adalah 1:60. Kelajuannya 1 ~ 7m / min boleh laras. Dilengkapi dengan penukar frekuensi Delta 750W VFD.

lebih-lebih lagi, penghantar boleh bergerak ke kedua-dua arah.

Catatan baik: peranti kawalan elektronik jenama lain juga ada, seperti FIG, Schneider atau Siemens. Selain itu, jenama termostat dan motor penghantar juga boleh disesuaikan.

Ciri-ciri Tungku Terowong Industri

1. Waktu pemanasan ketuhar penghantar inframerah cepat. Selain itu, suhu stabil dan tepat. Kerana penggunaan peredaran udara panas dan pemanasan inframerah, keseragaman suhu baik. Jadi kondusif untuk rawatan haba produk.

2. Menggunakan pengiraan automatik PID pengawal suhu pintar. dan, bekerjasama dengan relay keadaan pepejal SSR. Oleh itu, ia dapat mengawal ketepatan suhu dengan tepat.

3. Kerana kapas penebat haba, jalur pengedap dan pintu masuk tahan suhu tinggi & plat penghalang keluar, kesan penebat haba adalah baik. Pada masa yang sama, suhu kulit luar ketuhar terowong industri rendah. Oleh itu, terdapat sedikit kesan terhadap suhu persekitaran dalaman.

4. Dalam keadaan biasa, penutup atas ketuhar penghantar inframerah agak berat. Oleh itu, kami menambah silinder atau batang pengangkat elektrik ke conveyorfurnace. Ini memudahkan penyelenggaraan dan penggantian tiub pemanasan.

5. Alat kawalan elektrik selamat dan boleh dipercayai, dengan fungsi perlindungan suhu ganda ganda. Pada masa yang sama ia menggunakan butang kecemasan.

ulasan

Tiada ulasan lagi.