Penerangan

Penghantar aliran bebas juga ialah penghantar rantai roller terkumpul atau penghantar rantai kelajuan berganda. Sama dengan penghantar rantai biasa, ia juga mesin penghantar yang menggunakan rantai sebagai bahagian daya tarikan dan produk. Tetapi ada juga perbezaannya. Prinsip menyampaikan adalah menggunakan fungsi peningkatan kelajuan rantai berkelajuan dua kali. Oleh itu, palet bahan kerja yang menyokong produk dapat berjalan dengan cepat. Penghantar rantai aliran bebas digunakan terutamanya dalam barisan pengeluaran pemasangan. Ia dapat mewujudkan pelengkap setiap stesen kerja.

Apakah rantai penghantar aliran bebas?

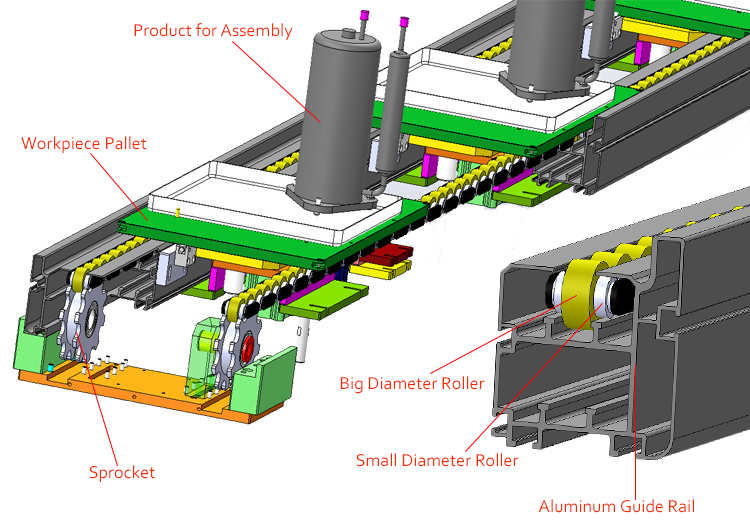

Berbeza dengan penghantar rantai biasa, ia menggunakan rantai roller terkumpul. Jadi apa perbezaan antara mereka? Bagaimana rantai penghantar aliran bebas berfungsi?

Di atas semua, rantai berkelajuan dua terdiri daripada penggelek berdiameter besar, penggelek berdiameter kecil dan pautan rantai sendi. Penggelek kecil berjalan di rel panduan, dan penggelek besar menyokong palet bahan kerja. When we drag the entire chain to move, it is actually small rollers moving on the guide rail. Sebaliknya, when the whole chain moves, the large rollers and the small rollers move synchronously. Dalam kata lain, when the small roller runs for one circle, the large roller also runs for one circle. Walau bagaimanapun, due to the difference in diameter, their actual movement distance in the horizontal direction is different. The running distance of the big roller is much greater than that of the small roller.

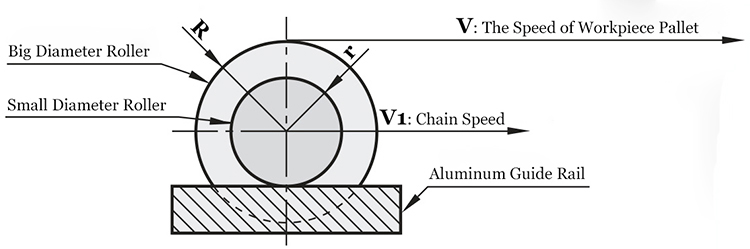

Sebagai contoh, the free flow conveyor chain runs at the speed of V1. Then the turnover speed of the small roller is V1. Pada masa ini, the turnover speed of the big roller is (R/r)*V1. Oleh itu, the running speed (V) of the workpiece pallet is the sum of the large roller speed and the chain speed. Itu dia, V=(R/r)*V1+V1=(R/r+1)*V1. If the ratio of the radius of the big roller to the small roller is 1.5:1, kelajuan palet penghantar adalah V =(1.5+1)*V1 = 2.5 * V1.

Kelajuan berjalan produk lebih cepat daripada rantai roller terkumpul. Oleh itu, kerana struktur khas rantai berkelajuan dua, ia menghasilkan kesan peningkatan kelajuan. Sudah tentu, kerana struktur rantai, peningkatan kelajuan rantai roller terkumpul adalah terhad. Kesan kelajuan biasa penghantar aliran bebas adalah V =(2~ 3)*V1. Spesifikasi umum adalah 2.5 rantaian penghantar kelajuan kali dan 3 rantaian penghantar kelajuan.

Mengapa perlu mengumpulkan penghantar rantai roller?

Garis pemasangan manual tradisional memerlukan pekerja di kedua-dua belah pihak. Sebagai contoh, ada talian pemasangan penghawa dingin. Putar skru di stesen pertama. Stesen kedua memasang bahagian lain. Stesen ketiga dilabel. Kecekapan operasi manual tidak selalu sangat tinggi. To improve production efficiency, kami mula menggunakan penghantar rantai aliran bebas.

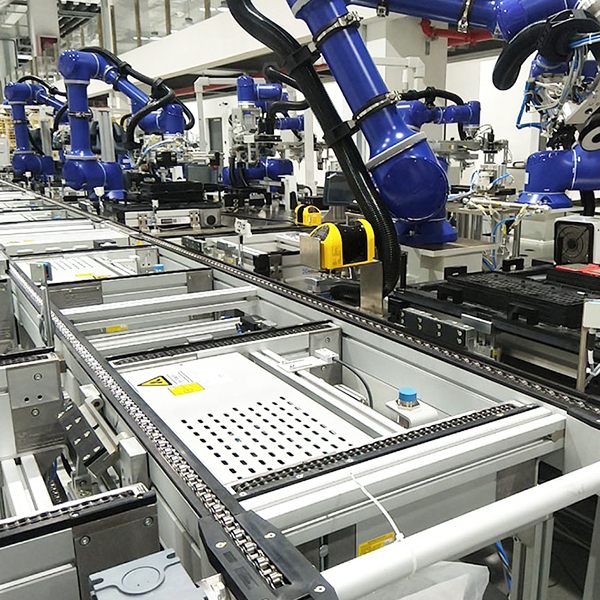

The accumulating roller chain can quickly move the pallet from one process to the next. Di barisan pemasangan penghantar rantai berkelajuan dua, setiap proses dikendalikan oleh robot. Untuk memudahkan operasi robot, ia menambah mekanisme penyekat.

Parameter Teknikal Penghantar Rantai Berkelajuan Berkembar

|

Free flow chain conveyor length |

2000mm~40000mm |

|

Workpiece pallet size |

160~800mm |

|

Ketinggian penghantar pemasangan palet |

Adat mengikut keperluan |

|

Kapasiti muatan maksimum (jumlah) |

200KG / 500KG /2000KG |

|

Menyampaikan kelajuan (beban maksimum) |

20m / min |

|

Medium penghantar |

08BS / Rantai roller terkumpul BS25 |

|

Bahan bingkai |

Profil aluminium khas |

|

Jenis pemasangan motor |

Pemacu akhir atau pemacu tengah |

Ciri-ciri Penghantar Rantai Roller

1. Pertama sekali, ia menggunakan profil aluminium khas sebagai rel panduan. Oleh itu, penghantar rantai berkelajuan dua mempunyai kestabilan dan ketahanan yang sangat baik semasa proses menyampaikan. Oleh itu, ia sesuai untuk pengeluaran produk secara berterusan.

2. Kedua, ia dapat menggerakkan benda kerja untuk jarak jauh. Dan kelajuan boleh menjadi cepat. Pada masa yang sama, ia dapat mewujudkan penyampaian jenis pengumpulan untuk mengelakkan berlakunya tunggakan bahan.

3. Ketiga, kapasiti menyampaikannya besar. Selain itu, free flow chain conveyor can carry a large load. Loads from 200KG to 2000KG are applicable.

4. It can meet the needs of a variety of production processes, such as glue dispensing, large screws, kimpalan, dan lain-lain.

5. Sebagai tambahan, accumulating roller chain conveyor can achieve a variety of test requirements, such as CCD vision, photoelectric detection, resistance detection, withstand voltage detection, product function detection, dan lain-lain.

6. Free flow conveyor can be applicable to various types of similar products. lebih-lebih lagi, if customers need to increase product types, they can quickly upgrade and transform.

7. The double-speed chain assembly conveyor is flexible. Sebagai contoh, when we need to improve production efficiency, we can increase the number of pallets and work stations. vice versa. Sebaliknya, it can also design complex product flow. Sebagai contoh, we can add horizontal traversing and turning devices to realize a horizontal circular assembly line. Or to achieve a more complex shape of the assembly line.

8. Akhirnya, it can realize intelligent manufacturing functions. The running data, inspection data and production data of the entire production line can be saved and summarized. So it’s convenient to read online or online.

How to choose free flow chain conveyor?

When you need to customize the free flow chain assembly conveyor, please confirm the below details:

1. Pertama, it needs to inform the size and weight of the product. Because this will affect the selection of tooling board and motor power.

2. Kedua, clarify the shape and layout of the accumulating roller chain conveyor. Is it a straight line, a horizontal loop or a vertical loop?

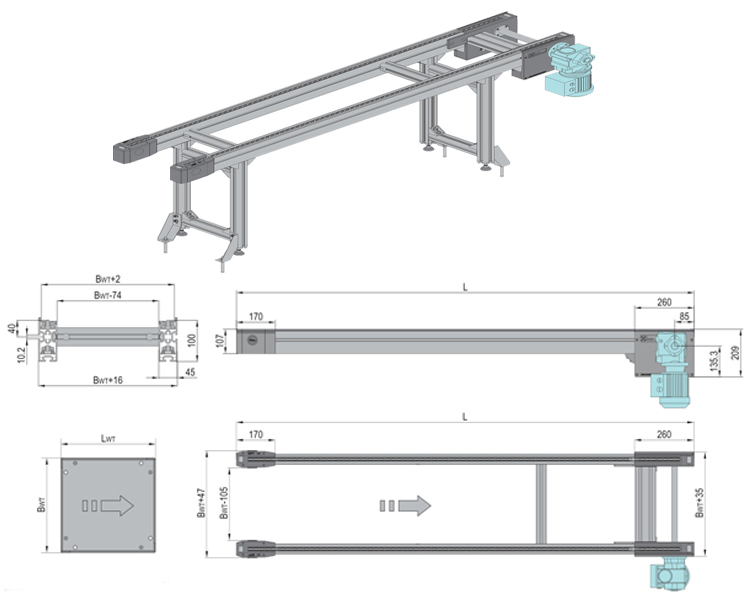

3. Ketiga, determine the size of the double-speed chain conveyor. The longest can be 30-40 meter. The width is generally 250~900mm (disesuaikan). Selain itu, the height is generally 500~1200mm.

4. Keempat, confirm the operating speed of the free flow chain conveyor. Secara amnya, the maximum speed is 20m/min.

5. Kelima, determine the type of double-speed chain. The speed is divided into 2.5 times and 3 kali. The large rollers can be stainless steel and engineering plastics.

6. Pemilihan bahan: there are a variety of materials for workpiece pallets to choose from, such as aluminum, keluli, engineering plastic, wood, dan lain-lain. Bahan kerangka pada umumnya profil aluminium dan keluli dicat.

7. Sebagai tambahan, adalah lebih baik untuk memberitahu aliran proses anda. Pada masa yang sama, maklumkan sama ada terdapat fungsi tambahan ke penghantar aliran bebas, seperti ujian produk.

8. Akhirnya, sahkan bekalan kuasa: 220V fasa tunggal / tiga fasa 380V 50Hz atau lain-lain.

Cara mengganti rantai penghantar aliran bebas?

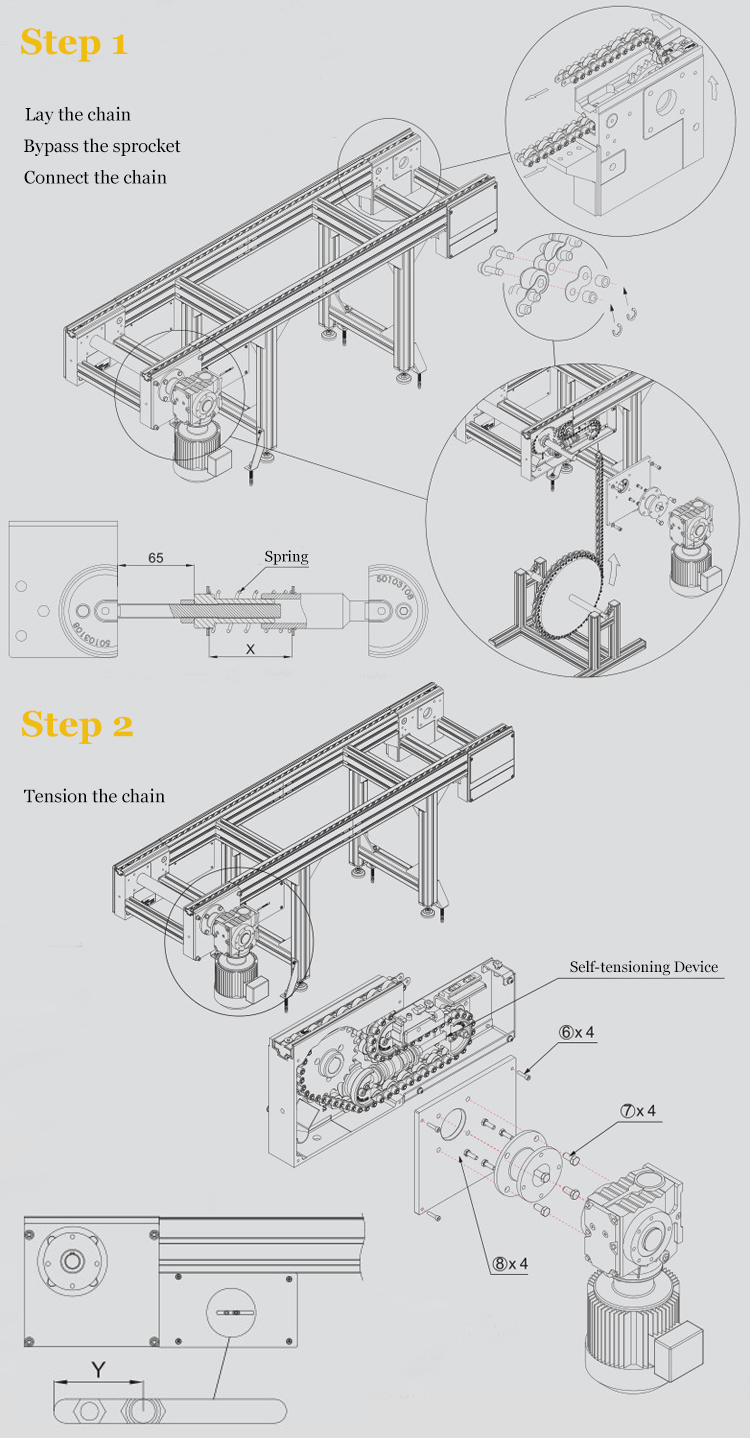

Sebenarnya, the installation of accumulating rolller chain conveyor is other chain conveyors. When you need to replace the free flow conveyor chain, remove the old chain firstly. Kemudian, place the chain on the chain shaft in order to avoid chain damage. And guide the chain trough the lower part of the drive unit. Sejurus selepas itu, bypass driven sprocket, the drive end and the drive sprocket in turn. Finally connect the double speed conveyor chain.

Similar to belt conveyor, free flow conveyor also needs to tighten the chain. Otherwise it will influence the load-bearing capacity of the conveyor assembly line.

Catatan baik: this free flow chain conveyor has self-tensioning device. It needs often observe the length of Y. Selain itu, it must ensure that 35≤Y≤55.

How to maintain accumulating roller chain conveyor?

Before starting the free flow chain conveyor daily, we should check whether there are fragments in the chain. Jika tidak, it will damage the chain. Sebagai tambahan, clean the assembly conveyor line each week. And often check if the double speed conveyor chain is loose. Pada masa yang sama, check whether the chain needs lubrication.

Chain lubrication

Before starting the free flow conveyor for the first time, you must lubricate chain. How to lubricate the chain? Drage the whole chain. Lubricate the chain with an amount of about 2~3ml/m. Recommend 15W40 Shell oil.

Sebagai tambahan, as long as the equipment is down for more than 6 bulan, you need re-lubricate it. Before lubricating, remove excess grease, oil stains or other impurities on the accumulating roller chain. Pada masa yang sama, check whether the chain is worn or stretched. Lubrication method and oil volume are the same as above.

During normal use of the assembly conveyor, it needs re-lubricate the chain every 1000 Jam. Lubricate a small amount each time-about 2ml/m. Sebagai tambahan, if the operating environment has high humidity, we should shorten the interval time between each lubrication according to the actual situation.

Sudah tentu, we can customize the self-lubrication system. It can optimally and uniformly lubricate the free flow conveyor chain during equipment operation.

When using the free flow conveyor, jika ada kecemasan, press the red emergency stop switch immediately. Then turn off the power and start the solution.

ulasan

Tiada ulasan lagi.