Apraksts

Moduļu montāžas līnija ir nesinhrona instrumentu dēļu pārsūtīšanas sistēma. Turklāt Sagataves konveijers ir efektīva platforma, kas veido montāžas un pārbaudes sistēmu. Palešu montāžas konveijers ir piemērots darbstacijām, kurām nepieciešama precīza pozicionēšana. Mēs to varam izmantot, lai izveidotu pusautomātiskas vai pilnībā automātiskas sistēmas.

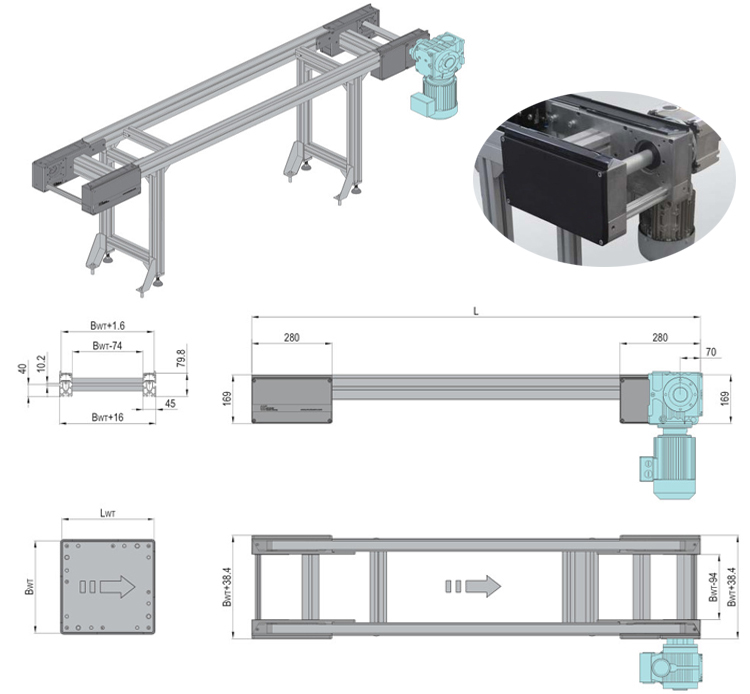

Moduļu palešu konveijers ir aprīkots ar paletēm un pacelšanu & pozicionēšanas vienība. Tāpēc, tas var realizēt augstas precizitātes automatizētu darbstaciju montāžu. Tas ir līdzīgs bosch palešu konveijeriem, piemēram, TS1, TS2, TS4, TS5 konveijers. Moduļu montāžas konveijeram ir ļoti labas priekšrocības. Jo katrs komponents ir standartizēts un modulēts, tā dizains ir elastīgāks. Turklāt, tas var brīvi pārvietoties no konveijera ražošanas līnijas. Tātad jūs varat elastīgi mainīt modulāro sagataves konveijeru dažādiem izstrādājumiem vai procesiem.

Šeit mēs iepazīstinām ar neilona bāzes lentes montāžas konveijeru ar slodzi 160 kg. Tās pielietojums ir šāds:

• Tas var realizēt augstas precizitātes automātisku darbstaciju montāžu. Tāpēc, to plaši izmanto automašīnu detaļu montāžas līnijās un automātisko ražošanas līnijās.

• Moduļu palešu konveijeram ir plaša pielāgojamība produkta izmēram. Tādējādi, to plaši izmanto elektroniskās ražošanas līnijās.

• Moduļu montāžas līnija ir stabila, sauss un tīrs. Tāpēc mēs to parasti izmantojam enerģijas akumulatoru konveijera līnijām, piemēram, akumulatoru montāžas līnijas, litija bateriju PACK līnijas un moduļu līnijas.

Moduļu montāžas līnijas palešu lentu konveijera tehniskā specifikācija:

|

Pallet assembly conveyor length |

600~1200mm |

|

Sagataves paletes izmērs |

160~ 640mm |

|

Workpiece conveyor height |

Customizable as request |

|

Maksimālā kravnesība (Kopā) |

160KILOGRAMS |

|

Conveyor speed (max slodze) |

5~ 20m / min |

|

Konveijera vide |

30mm width anti-static nylon base belt |

|

Rāmja materiāls |

Alumīnija profils |

|

Motora uzstādīšanas veids |

Beigt piedziņu vai centrālo piedziņu |

|

Stands spacing |

800~1600mm, vai pasūtījuma |

Laipna piezīme: the load capacity is the total load. Unit load capacity of workpiece conveyor≤0.6kg/cm.

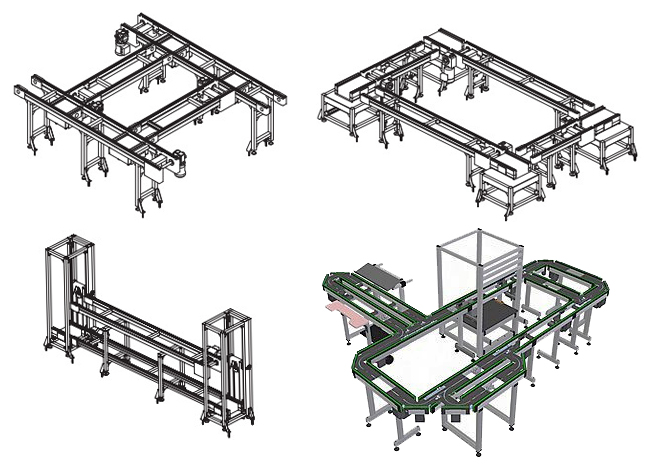

The modular pallet assembly conveyor can have different layouts as requests. It can be horizontal circulation assembly system, vertical circulation system or other complicated layouts.

Characteristics of Modular Workpiece Conveyor

① Firstly, this kind of assembly line conveyor is suitable for small load (Max 160KG).

② Secondly, easy to use, fast delivery, beautiful appearance and convenient maintenance.

③ It is possible to add a lifting device or a lateral turning device to the system. In this way, it can make a circular assembly system. Tāpēc, modular assembly line can reduce the floor space.

④ Flexible design allows customers to use workpiece pallets of different sizes on the same system. Thus it help customers to assemble a variety of products. So it save the costs.

⑤ The pallet assembly conveyor system adopts aluminum profile frame. Tajā pašā laikā, each unit is a modular design. Tāpēc, it can be very flexible in a convenient combination for various occasions. So it can quickly meet the requirements of various automatic production lines.

Laipna piezīme: the conveying direction of pallet assembly conveyor must follow the arrow in the figure above.

How to install / assemble the modular pallet assembly conveyor?

Because of the simple structure of the modular workpiece conveyor, our shipments are in the form of accessories. Protams, the assembly is very simple. You can refer to the following instructions to assemble.

1. Pirmkārt, if your workpiece conveyor compose of two or more section parts, join them together as the picture.

2. Otrkārt, mount the guide rails onto the stands. And adjust the foot height in order to make the conveyor stable.

3. Treškārt, install the drive unit and driven unit onto the guide rails of modular assembly line.

4. Immediately after, install the conveyor belt of pallet assembly conveyor:

① Above all, confirm the upper and lower layers of the adhesive surface of the belt according to conveying direction. Then install the belt onto the drive wheel.

② Pull up the two belts and fix them on the auxiliary profile with the clamping blocks. Then connect the chain block with auxiliary profile on one end and auxiliary steel shaft on the other end. Tighten the chain block. And make the clamping block and auxiliary profile move to the driven end. Finally install the conveyor belt onto the driven wheel.

③ Afterwards, fix the head end friction strip and blocking plate onto the casing of drive / driven unit. Then disconnect the chain block and clamping block. And the conveyor belt will be tensioned automatically.

So far, it completes installation process of the modular pallet assembly conveyor. Papildus, if you want to replace the belt, please cut the wear strip at the end, and then take out the old belt. Finally follow the steps above to install the belt.

How to maintain modular assembly line conveyor system?

Although the modular pallet assembly conveyor has stable performance, it also needs timely maintenance. Piemēram, you need clean the workpiece conveyor in time. Tajā pašā laikā, replace damaged spare parts. And to do preventive maintenance work.

1. Daily maintenance

Before starting the modular assembly line every day, check it carefully. To avoid objects falling on it. If there is, it must be cleared in time. Citādi, it will damage machine.

2. Weekly maintenance

Clean the pallet assembly conveyor each week. Laipna piezīme: Do not use lubricating oil or cleaning agents that will corrode the machine.

3. Monthly maintenace

Check the parts that may be loose every month. If so, fasten them.

4. Quarterly maintenance

Check whether the circuit is damaged. The focus is on the various wiring positions of the modular assembly line.

Atsauksmes

Vēl nav nevienas atsauksmes.