Katrangan

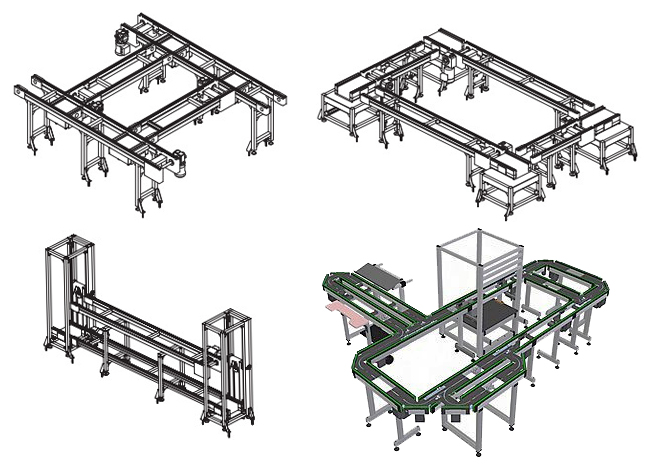

This pallet assembly line belt conveyor adopts timing belts for silent conveying. It is a kind of modular assembly line conveyor systems. Sepisanan, nggunakake palet workpiece minangka operator kanggo ngirim produk. Banjur, palet gerakane ing sabuk wektu sing untu. Nyatane, baris perakitan modular iki kaya conveyor palet TS bosch. Amarga desain modular, tata letak fleksibel. Sanalika, akeh perusahaan nggunakake kanggo nglumpukake lan nyoba produk.

Minangka assembly line conveyor manufacturer, kita bisa ngatur sawetara lini produksi conveyor. Contone, kita bisa ngasilake conveyor assemble belt wektu kanggo acara ringan. Beda karo conveyor aliran bebas, kapasitas muatan maksimal yaiku 60KG. Dadi conveyor workpiece jenis iki duwe aplikasi sing akeh kanggo komponen elektronik lan otomotif.

Bisa nyadari konversi antarane stasiun lan stasiun. Sanalika, bisa mujudake reflek lapisan ndhuwur lan ngisor palet workpiece. Conveyor sabuk wektu bisa nambah komponen liyane kanggo mbentuk sistem konektor garis perakitan sing luwih kompleks. Contone, bisa nambah pengangkat beban ringan kanggo mbentuk garis perakitan sirkulasi vertikal. Kajaba iku, uga bisa nambah mekanisme lan sensor mandeg kanggo mungkasi lan ngeculake produk.

Parameter Teknis Conveyor Sabuk Line Majelis Modular

|

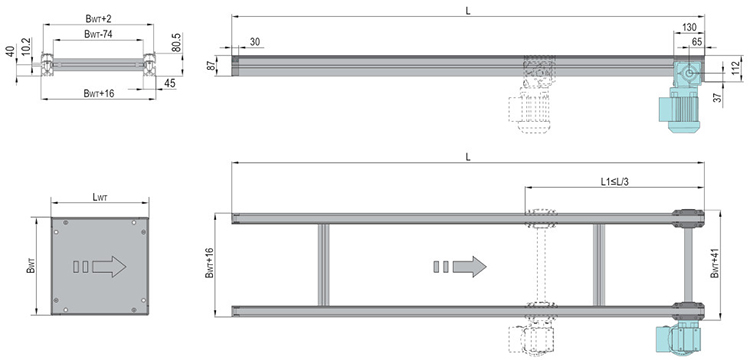

Dawa conveyor modular dawa |

220~ 6000mm |

|

Ukuran papan perkakas |

160~ 640mm |

|

Dhuwur conveyor Déwan palet |

Custom kaya kabutuhan |

|

Kapasitas beban maksimal (gunggunge) |

60KG |

|

Kacepetan ngirimake (maksimal mbukak) |

5~ 20m / min |

|

Media konveyor |

Sabuk wektu sing untu |

|

Bahan bingkai |

Profil aluminium |

|

Jinis instalasi motor |

Pungkasi drive utawa drive tengah |

Karakteristik & Keuntungan Sistem Konveyor Line Assembly

1. Kaping kabeh, konektor rakitan palet iki cocog kanggo acara momotan ringan.

2. Kapindho, sampeyan bisa nambah puteran, unit pengangkat lan traverse kanggo nyadari kontrol siklus otomatis.

3. Kaping telune, komponen sing wis dirancang ngirit biaya lan wektu kanggo para pelanggan. Sanalika, subsequent maintenance is simple and convenient.

4. Kaping papat, strong applicability. It can change the assembly line conveyor system for different products or processes. Mula, it is especially suitable for industries with fast product replacement, such as the electronics industry.

5. Pungkasane, the system has high accuracy. Various high-precision guidance, posisi, detection components are used on the machine. Thereby, njamin presisi tinggi perakitan produk.

Introduction of Modular Wokpiece Pallet Tooling Board

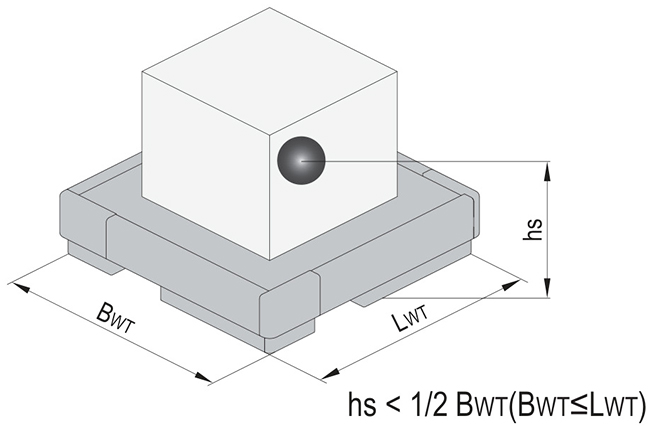

The pallet acts as the transferring tool to convey the workpiece to each work station.The modular pallet will be stopped by the blocker when it arrives at the work station.

| BWT(mm) | LWT(mm) | Frame Weight-A (KG) | Max Uniform Load (KG) |

|

160 |

160 | 1.51 | 16 |

| 240 | 2.04 | 16 | |

| 320 | 2.58 | 16 | |

|

240 |

240 | 2.67 | 24 |

| 320 | 3.32 | 24 | |

| 400 | 3.89 | 24 | |

| 480 | 4.51 | 24 | |

|

320 |

320 | 3.99 | 32 |

| 400 | 4.69 | 32 | |

| 480 | 5.40 | 32 | |

|

400 |

400 | 5.60 | 40 |

| 480 | 6.39 | 40 | |

| 480 | 480 | 7.28 | 48 |

| 640 | 640 | 9.71 | 64 |

Karakteristik & Advantages of Modular Conveyor Workpiece Pallet

1. The workpiece pallet composes of anti-static corner seat and aluminum profile support frame.

2. Because the modular conveyor pallet is with high-precision positioning pin sleeves, the positioning accuracy can reach ±0.1mm. So assembly line belt conveyor can meet high accuracy assembly requirement.

3. The carrying capacity of the pallet is 2kg/cm in the length direction.

4. In order to ensure the life, the pallet load needs to be evenly distributed at the center of the pallet.

5. The standard sensor gasket is used to detect the position of the pallet with the proximity switch.

6. The tooling pallet is made of 5mm, 8mm or 12mm thick steel plate or aluminum plate. The aluminum plate is anodized. The steel plate is treated with black electrophoresis.

Ulasan

Durung ana review.