Deskripsi

Jalur perakitan modular adalah sistem transfer papan perkakas non-sinkron. Selain Konveyor benda kerja adalah platform efisien yang menyusun sistem perakitan dan pengujian. Konveyor perakitan palet cocok untuk stasiun kerja yang membutuhkan pemosisian yang tepat. Kita dapat menggunakannya untuk membangun sistem semi-otomatis atau sepenuhnya otomatis.

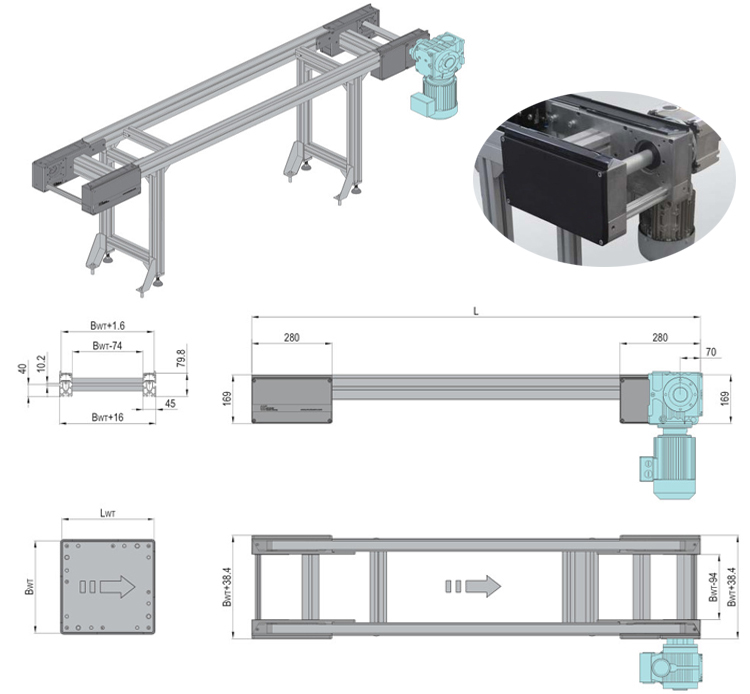

Konveyor palet modular dilengkapi dengan palet dan pengangkat & unit pemosisian. Karena itu, itu dapat mewujudkan perakitan stasiun kerja otomatis presisi tinggi. Ini mirip dengan konveyor palet bosch, seperti TS1, TS2, TS4, konveyor TS5. Konveyor perakitan modular memiliki keuntungan yang sangat baik. Karena setiap komponen terstandarisasi dan termodulasi, desainnya lebih fleksibel. Bahkan, itu dapat berpindah dari jalur produksi konveyor dengan bebas. Jadi Anda dapat secara fleksibel mengubah konveyor benda kerja modular untuk berbagai produk atau proses.

Di sini kami memperkenalkan konveyor perakitan sabuk nilon dengan beban 160KG. Aplikasinya adalah sebagai berikut::

• Dapat mewujudkan perakitan stasiun kerja otomatis presisi tinggi. Karena itu, itu banyak digunakan di jalur perakitan suku cadang mobil dan jalur produksi otomatis otomatis.

• Modular pallet conveyor has wide product size adaptability. Jadi, it has wide application in electronic production lines.

• The modular assembly line is stable, dry and clean. Jadi kami biasanya menggunakannya untuk jalur konveyor baterai energi, seperti jalur perakitan baterai, garis PACK baterai lithium dan garis modul.

Technical Specification of Modular Assembly Line Pallet Belt Conveyor:

|

Pallet assembly conveyor length |

600~1200mm |

|

Ukuran palet benda kerja |

160~640mm |

|

Workpiece conveyor height |

Customizable as request |

|

Kapasitas beban maksimum (total) |

160KG |

|

Kecepatan konveyor (beban maksimal) |

5~20m/mnt |

|

Media konveyor |

30mm width anti-static nylon base belt |

|

Bahan bingkai |

Profil aluminium |

|

Jenis pemasangan motor: |

Drive akhir atau drive tengah |

|

Stands spacing |

800~1600mm, atau kustom |

Catatan baik: the load capacity is the total load. Unit load capacity of workpiece conveyor≤0.6kg/cm.

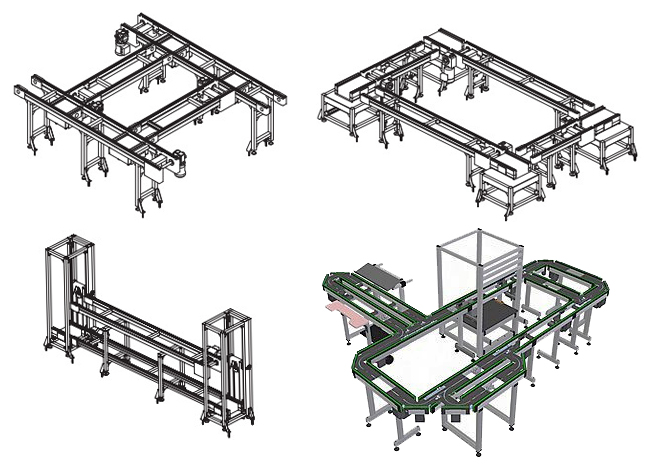

The modular pallet assembly conveyor can have different layouts as requests. It can be horizontal circulation assembly system, vertical circulation system or other complicated layouts.

Characteristics of Modular Workpiece Conveyor

Pertama, this kind of assembly line conveyor is suitable for small load (Max 160KG).

Kedua, easy to use, fast delivery, beautiful appearance and convenient maintenance.

③ It is possible to add a lifting device or a lateral turning device to the system. Lewat sini, it can make a circular assembly system. Karena itu, modular assembly line can reduce the floor space.

④ Flexible design allows customers to use workpiece pallets of different sizes on the same system. Thus it help customers to assemble a variety of products. So it save the costs.

⑤ The pallet assembly conveyor system adopts aluminum profile frame. Pada waktu bersamaan, each unit is a modular design. Karena itu, it can be very flexible in a convenient combination for various occasions. So it can quickly meet the requirements of various automatic production lines.

Catatan baik: the conveying direction of pallet assembly conveyor must follow the arrow in the figure above.

Bagaimana cara meng-install / assemble the modular pallet assembly conveyor?

Because of the simple structure of the modular workpiece conveyor, our shipments are in the form of accessories. Tentu saja, the assembly is very simple. You can refer to the following instructions to assemble.

1. Pertama tama, if your workpiece conveyor compose of two or more section parts, join them together as the picture.

2. Kedua, mount the guide rails onto the stands. And adjust the foot height in order to make the conveyor stable.

3. Ketiga, install the drive unit and driven unit onto the guide rails of modular assembly line.

4. Immediately after, install the conveyor belt of pallet assembly conveyor:

① Above all, confirm the upper and lower layers of the adhesive surface of the belt according to conveying direction. Then install the belt onto the drive wheel.

② Pull up the two belts and fix them on the auxiliary profile with the clamping blocks. Then connect the chain block with auxiliary profile on one end and auxiliary steel shaft on the other end. Tighten the chain block. And make the clamping block and auxiliary profile move to the driven end. Finally install the conveyor belt onto the driven wheel.

③ Afterwards, fix the head end friction strip and blocking plate onto the casing of drive / driven unit. Then disconnect the chain block and clamping block. And the conveyor belt will be tensioned automatically.

So far, it completes installation process of the modular pallet assembly conveyor. Tambahan, if you want to replace the belt, please cut the wear strip at the end, and then take out the old belt. Finally follow the steps above to install the belt.

How to maintain modular assembly line conveyor system?

Although the modular pallet assembly conveyor has stable performance, it also needs timely maintenance. Sebagai contoh, you need clean the workpiece conveyor in time. Pada waktu bersamaan, replace damaged spare parts. And to do preventive maintenance work.

1. Daily maintenance

Before starting the modular assembly line every day, check it carefully. To avoid objects falling on it. If there is, it must be cleared in time. Jika tidak, it will damage machine.

2. Weekly maintenance

Clean the pallet assembly conveyor each week. Catatan baik: Do not use lubricating oil or cleaning agents that will corrode the machine.

3. Monthly maintenace

Check the parts that may be loose every month. Jika begitu, fasten them.

4. Quarterly maintenance

Check whether the circuit is damaged. The focus is on the various wiring positions of the modular assembly line.

Ulasan

Belum ada ulasan.