Stainless Steel Z Type Bucket Elevator Conveyor

Z shaped bucket elevator capacity: 4~22m³/h (or custom);

Bucket conveyor system speed: 10~15m/min;

Machine body material: SS304 stainless steel;

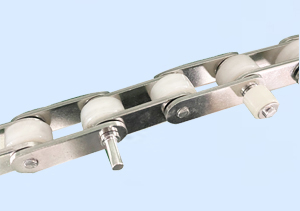

Sprocket / chain: alloy steel or stainless steel;

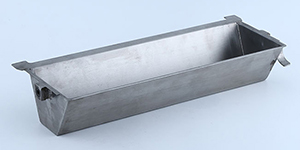

Elevator buckets material: ABS or SS304 stainless steel;

Bucket volume: 1L, 1.8L, 2.4L, 3.6L, 6.5L, 10L;

Voltage: 3-phase 380V or 220V;

Description

Z type bucket elevator has wide application to transport many kinds of bulk materials, powder and particulate matter. For example, we usually use the z bucket elevator to convey grain, beans, rice, food, flour, cement, etc. As the Z shaped bucket conveyor system manufacturer, we can design & customize the bulk elevator with ABS plastic and stainless steel buckets. Z bucket conveyor has large conveying capacity. Moreover, z style bucket elevator not only has the function of horizontal conveyor, but also can work as vertical lift conveyor.

Compared to inclined bucket conveyor, z elevator conveyor occupies a smaller area. Besides, it has many advatanges and features. Bucket elevator structure and components are simple. So operation and maintenance is convenient. If you have high sanitary requirements in food industry, it can choose the food grade elevator buckets.

What is Z type bucket elevator?

In the closed shell, the bulk materials are along the Z-shaped material conveying direction. So Z bucket elevator is a multifunctional vertical elevator. Z type elevator has the characteristics of both horizontal and vertical conveying. There is a feed port at the lower end. And discharge port is on the upper end. The feeding port is generally equipped with a feeding device, such as an electromagnetic vibrating feeder. Additionally, there are many buckets on the elevator chains. Then the elevator buckets load and conveyor bulk materials.

What is a Z bucket elevator used for?

1. Firstly, food industry is the most wide application: nuts, peanuts, cocoa beans, biscuits, potato chips, fried foods, dumplings, chocolate, sugar, frozen foods, flour, etc.;

2. Secondly, the z bucket elevator is also suitable for the grain industry, such as grain, rice, beans, seeds, etc.;

3. Thirdly, the chemical industry, such as plastic particles (PP, PE, PS), activated carbon, preservatives, additives, feed, fertilizers, cement, etc.;

4. Fourthly, the bucket conveyor system can be used in the pharmaceutical industry, such as capsules, tablets, pills, etc.;

5. Fifth, the z type bucket elevator is also applicable for the hardware industry, such as screws, nuts, and metal parts.

Specification of Z Style Bucket Conveyor System

Elevator machine body: SS304 stainless steel casing;

Bucket: plastic or stainless steel elevator buckets available;

Bucket elevator chain: alloy steel or stainless steel chain;

Conveyor sprocket: alloy or stainless steel sprocket;

Motor: ordinary gear motor or exlosion-proof motor;

Z type elevator speed: 10~15m/min (speed adjustable);

Conveying capacity: 4~22m³/h (or customizable);

Bucket volume: 1.8L, 3L, 4L, 6.5L, 10L;

|

Z Bucket Elevator Model |

ZD-2L |

ZD-3L |

ZD-4L |

ZD-6.5L |

ZD-10L |

|

Z Elevator Capacity |

0~6m3/h |

0~8m3/h |

0~12m3/h |

0~15m3/h |

0~22m3/h |

|

Bucket Volume |

1.8L |

2.4L |

3.6L |

6.5L |

10L |

|

Lifting Height |

Up To 50m |

||||

|

Power of Bucket Conveyor system |

0.75~22KW |

||||

Z bucket conveyor features & advantages:

- 1. Above all, there are several materials for choice. And the z type bucket elevator components have high quality. So it ensures the service life of bucket conveyor system. At the same time, the guarantee smooth operation. Moreover, they are easy to disassemble and clean.

2. Secondly, the z elevator sprocket is precision machined and is wear-resistant. The chain adopts a buckle design, thus it is easy for replacement. Besides, it can be better protection for elevator buckets. At the same time, it ensures low noise.

3. Thirdly, use the vibrating feeder hopper. Compared with ordinary hoppers, it can ensure uniform feeding.

4. Fourthly, there is VFD controller in the electric control box. So you can adjust the speed of z type bucket elevator easily.

5. There is z bucket elevator tensioning device. Therefore, it can adjust the chain tightness.

6. The warranty time of our bucket conveyor motor is 1 year. In addition, within 2 years, we can supply free bucket elevator components for replacement.

How does a bucket conveyor system work?

When the Z shaped bucket conveyor system is working, the geared motor drives the sprockets to move synchronously. So it makes the two chains run synchronously. The buckets reach the top horizontal section. With the action of the overturning sprocket, the buckets turn down. As a result, the products fall into other supporting equipment from the discharge port.

Because the elevator buckets run on a closed track, there is no dust. At the same time, during transporation, there will be no product breakage problem.

Reviews

There are no reviews yet.