Description

This is a custom tunnel furnace drying oven for a client. They use it to dry pharmaceutical bottles. So its heating temperature is not high (85℃). It is a kind of continuous belt dryer. (Of course, we also usually customize high temperature conveyor dryer). The total length of this mesh belt furnace is 8.6 meters. It has 6 heating zones. At the corner of the tunnel dryer, it is a 90° curve PVC belt conveyor. Other 2 conveyor machines use the Teflon mesh belt.

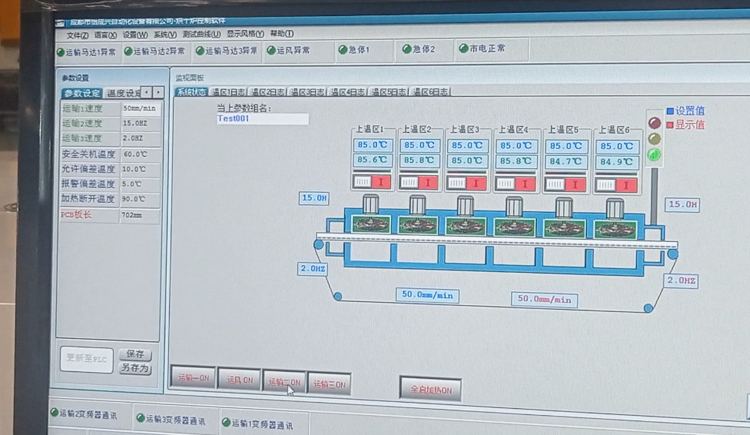

It’s a industrial infrared conveyor oven. Each drying zone has 6 pcs IR heating tubes. In addition, this continuous tunnel furnace is a control system. Customer can easily operate and control the mesh belt furnace on computer.

What is tunnel furnace oven?

It is a kind of continuous belt dryer. Different from drying oven, it has conveyor to transfer the products. So it doesn’t need people move the products frequently. Because the conveyor dryer looks like a tunnel, it is often called the tunnel furnace. You can use the mesh belt dryer together with other production assembly lines. So tunnel oven has many characteristics, such as high production efficiency, labor saving, and stable baking quality.

This tunnel oven consists of teflon belt conveyor, curved PVC belt conveyor, heating oven and temperature control system. Firstly, the products enter the belt furnace from the entrance zone. Then the conveyor belt moves the product at the set speed. The heating element in the conveyor oven dries the product. When the drying is complete, the products come out of the exit zone.

How does continuous tunnel furnace work?

At present, hot air circulation is a common heating method for conveyor dryer. It uses the principle of convection conduction to heat. And the heating element adopts the infrared heater tubes. The IR heating tube is located on the upper cover of conveyor oven. In addition, there is a fan in the belt furnace. Infrared-sensing light sources can shine in every corner of belt furnace. At the same time, the internal warm air circulation system promotes a more even temperature inside tunnel furnace. In addition, aluminum silicate fiber is filled between the inner liner and the outer shell as an insulation layer. So insulation performance is good.

Each working zone of continuous belt dryer is independently controlled. Because of the thermostat, it can control the temperature of conveyor tunnel oven in real time. And temperature tolerance of our conveyor dryer can reach ±3℃.

Technical specification of continuous belt dryer

Below are the technical specifications of 6 heating zones tunnel furnace as above video. Of course, we can customize the tunnel conveyor oven as customer’s requirements.

-

1. Mesh belt conveyor

- The conveyor consists of 2 sets of teflon mesh belt conveyor and 1 set of 90° curve conveyor. The belt width is 800mm. Under the mesh belt is a 1.5mm galvanized carrying plate with holes. Each conveyor uses 750W 3-phase motor with Delta brand VFD frequency converter. And conveying speed of the continuous belt dryer is 0~5 m/min adjustable.

The stands of conveyor belt furnace are 40*40mm painted carbon steel tubes. And there are height-adjustable feet. The mesh belt conveyor uses φ50mm driving and driven rollers. And curved conveyor uses cone rollers.

2. Heating oven

There are 6pcs of heating zones in this tunnel furnace. The outermost are outer convers for each oven. The material is painted carbon steel plate. The bracket can support the shell. Below the outer shell is the inner shell. The material is stainless steel plate. In addition, there are electric push rods to lift the inner shells. So it is convenient for customers to repair the conveyor belt furnace. And the height of entrance area is 100mm.

Each conveyor oven uses 6pcs of infrared heater tubes. The IR heating tubes are installed on the stainless steel mirror plate. The wind motor is Taiwan brand 750W motor. And the impeller fan is connected to the wind motor. Centrifugal fan impleller can effectively promote the circulation of hot air in the furnace. Additionally, there are high temperature resistant sealing strips. So it can avoid heat escaping. The surface of tunnel furnace oven adopts white color powder-coating. And there are exhaust vents on continuous belt dryer.

3. Control system

This continuous belt dryer has intelligent control system. So you can directly control the tunnel belt furnace on the computer. For example, it can adjust the conveyor speed and drying temperature. It uses the RKC brand thermostat. Automatic constant temperature control. Other control circuit appliances adopt Chint Electric. In addition, there are emergency control button, over-temperature power-off alarm, leakage protection, motor overload protection and other functions.

Operation instruction of continuous belt dryer

In order to protect the health and safety of end users, help users choose safe methods to operate the conveyor belt furnace. The use method and precautions of the tunnel furnace are as follows.

1. Installation and power distribution requirements

Adjust the feet to ensure that the conveyor dryer is level and stable.

Input power: three-phase five-system, 380V, 50HZ/60HZ;

Maximum power: 54KW;

Power cord: three-phase five-wire, the power cord is not less than 6m㎡;

Ensure that continuous belt dryer is well grounded to prevent personal safety due to leakage.

2. Operate the continuous tunnel furnace

(1) Start the conveyor dryer

Firstly, open the control electric box and the air switch.

Secondly, press the power button. Then directly operate the system on the computer. Turn on the conveyor and the conveyor belt starts to run. Next, start the wind motor. So centrifugal impleller fan starts to work.

Thirdly, set the working temperature of conveyor belt furnace. Enter the drying temperature directly on the computer. At the computer also shows the actual temperature in the tunnel oven.

In addtion, it can also set the belt conveyor speed on the computer. So customer can control the drying time.

(2) Shut down the continuous belt dryer

First, check whether all the products in the tunnel dryer out of the equipment.

Secondly, turn off the temperature control switches, from “on” to “off”

Thirdly, run empty for 10-15 minutes

Then, turn off the conveyor, wind motor and power supply in turn.

Finally, turn off the air switch and the main power supply.

Additionally, if there is an emergency, you can press the emergency button.

3. Conveyor belt furnace maintenance

Press the buttons to lift the outer covers of the tunnel furnace. So you can fix the tunnel oven and exchange the heating lamps.

After a period of normal operation, the conveyor dryer needs frequent maintenance.

Customer can adjust the conveyor belt by the tensioning device. It can prevent deviation of oven conveyor belt.

Pay attention to keep the electric box clean. To avoid accumulation of dust, electrical short-circuit phenomenon occurs.

Lubricate the conveyor chain every week.

In addition, always check the fixing bolts of the belt furnace and conveyor to prevent loosening.

FAQ

Q1: If we use the conveyor belt furnace to dry the injection parts, will it change the plastic size?

A1: If the drying temperature of tunnel furnace is high, it wil change the product sizes. But for injection plastic parts, the heating temperature is usually not high, so it doesn’t change plastic sizes.

Q2: What’s the appplication of the continuous belt dryer?

A2: This industrial tunnel oven is special for drying pharmaceutical bottles. Of course, this conveyor dryer can be also suitable for screen printing, cosmetic bottles, injection plastic parts, PCB, electronic products, etc.

Q3: What is the drying time in continuous tunnel furnace?

A3: Our customer uses this conveyor belt furnace to dry pharmaceutical bottles for 16 minutes each time. Of course, you can adjust the conveying speed to change the drying time.

Q4: What is the difference between tray dryer and tunnel dryer?

A4: Tray dryer is suitable for small batch drying. But it’s not for big batch baking. At this time, it needs tunnel conveyor dryer.

Reviews

There are no reviews yet.