Cur síos

Is saincheaptha é seo foirnéise tolláin oigheann a thriomú do chliant. Úsáideann siad é chun buidéil chógaisíochta a thriomú. Mar sin níl a teocht téimh ard (85℃). Is cineál de triomadóir crios leanúnach. (Ar ndóigh, is gnách go ndéanaimid triomadóir iompair ardteochta a shaincheapadh freisin). Fad iomlán an mhogalra seo foirnéise crios is 8.6 méadar. Tá sé 6 criosanna téimh. Ag cúinne an triomadóra tolláin, is iompróir crios PVC cuar 90 ° é. Eile 2 úsáideann meaisíní iompair crios mogalra Teflon.

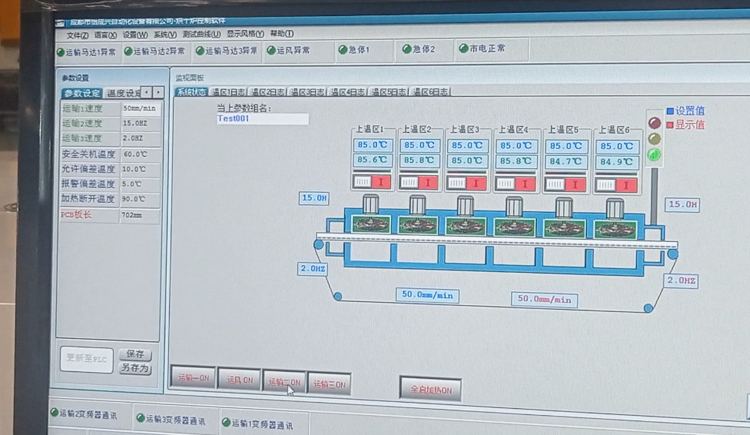

Is oigheann iompair infridhearg tionsclaíoch é. Tá ag gach crios triomú 6 feadáin téimh IR ríomhaire. Freisin, is córas rialaithe é an foirnéis tolláin leanúnach seo. Is féidir le custaiméirí an foirnéis crios mogalra a oibriú agus a rialú go héasca ar ríomhaire.

Cad é oigheann foirnéise tolláin?

Is cineál triomadóir crios leanúnach é. Difriúil ó oigheann a thriomú, tá iompróir aige chun na táirgí a aistriú. Mar sin ní gá do dhaoine na táirgí a bhogadh go minic. Toisc go bhfuil cuma an tolláin ar an triomadóir iompair, is minic a thugtar foirnéis an tolláin air. Is féidir leat an triomadóir crios mogalra a úsáid in éineacht le línte cóimeála táirgeachta eile. Mar sin tá go leor tréithe ag oigheann tolláin, cosúil le héifeachtacht táirgeachta ard, sábháil saothair, agus cáilíocht bácála cobhsaí.

Is éard atá san oigheann tolláin seo iompróir crios teflon, iompróir crios cuartha PVC, oigheann téimh agus córas rialaithe teochta. Ar dtús, téann na táirgí isteach sa bhfoirnéis crios ón gcrios iontrála. Ansin bogann an crios iompair an táirge ag an luas socraithe. Déanann an eilimint téimh san oigheann iompair an táirge a thriomú. Nuair a bhíonn an triomú críochnaithe, tagann na táirgí as an gcrios imeachta.

Conas a oibríonn foirnéis tolláin leanúnach?

Faoi láthair, is modh téimh coitianta é aerchúrsaíocht te le haghaidh triomadóir iompair. Úsáideann sé prionsabal an seolta comhiompair chun teas. Agus glacann an eilimint téimh na feadáin téitheoir infridhearg. Tá an feadán teasa IR suite ar chlúdach uachtarach an oigheann iompair. Freisin, tá lucht leanúna san fhoirnéis crios. Is féidir le foinsí solais braite infridhearg taitneamh a bhaint as i ngach cúinne den fhoirnéis crios. Ag an am céanna, cuireann an córas inmheánach aerchúrsaíochta teocht níos cothroime chun cinn taobh istigh den fhoirnéis tolláin. Freisin, líontar snáithín alúmanaim alúmanaim idir an línéar istigh agus an bhlaosc seachtrach mar chiseal inslithe. Mar sin tá feidhmíocht inslithe go maith.

Déantar gach crios oibre de thriomadóir crios leanúnach a rialú go neamhspleách. Mar gheall ar an teirmeastat, féadfaidh sé teocht oigheann tolláin iompair a rialú i bhfíor-am. Agus is féidir le lamháltas teochta ár dtriomadóir iompair ± 3 ℃ a bhaint amach.

Sonraíocht theicniúil triomadóir crios leanúnach

Seo thíos sonraíochtaí teicniúla 6 foirnéis tolláin criosanna téimh mar atá thuas. Ar ndóigh, is féidir linn an oigheann iompair tolláin a shaincheapadh mar riachtanais an chustaiméara.

-

1. Iompróir crios mogalra

- Is éard atá sa iompróir 2 tacair de iompróir crios mogalra teflon agus 1 tacar iompróra cuar 90 °. Is é leithead an crios 800mm. Faoin crios mogalra tá pláta iompair ghalbhánuithe 1.5mm le poill. Úsáideann gach iompróir mótar 3-chéim 750W le tiontaire minicíochta VFD branda Delta. Agus tá luas iompair an triomadóra crios leanúnach inchoigeartaithe 0 ~ 5 m / nóim.

Is feadáin chruach carbóin péinteáilte 40 * 40mm iad seastáin na foirnéise crios iompair. Agus tá cosa inchoigeartaithe airde ann. The mesh belt conveyor uses φ50mm driving and driven rollers. And curved conveyor uses cone rollers.

2. Heating oven

There are 6pcs of heating zones in this tunnel furnace. The outermost are outer convers for each oven. The material is painted carbon steel plate. The bracket can support the shell. Below the outer shell is the inner shell. The material is stainless steel plate. Freisin, there are electric push rods to lift the inner shells. So it is convenient for customers to repair the conveyor belt furnace. And the height of entrance area is 100mm.

Each conveyor oven uses 6pcs of infrared heater tubes. The IR heating tubes are installed on the stainless steel mirror plate. The wind motor is Taiwan brand 750W motor. And the impeller fan is connected to the wind motor. Centrifugal fan impleller can effectively promote the circulation of hot air in the furnace. chomh maith, there are high temperature resistant sealing strips. So it can avoid heat escaping. The surface of tunnel furnace oven adopts white color powder-coating. And there are exhaust vents on continuous belt dryer.

3. Control system

This continuous belt dryer has intelligent control system. So you can directly control the tunnel belt furnace on the computer. Mar shampla, it can adjust the conveyor speed and drying temperature. It uses the RKC brand thermostat. Automatic constant temperature control. Other control circuit appliances adopt Chint Electric. Freisin, there are emergency control button, over-temperature power-off alarm, leakage protection, motor overload protection and other functions.

Operation instruction of continuous belt dryer

In order to protect the health and safety of end users, help users choose safe methods to operate the conveyor belt furnace. The use method and precautions of the tunnel furnace are as follows.

1. Installation and power distribution requirements

Adjust the feet to ensure that the conveyor dryer is level and stable.

Input power: three-phase five-system, 380V., 50HZ/60HZ;

Maximum power: 54KW;

Power cord: three-phase five-wire, the power cord is not less than 6m㎡;

Ensure that continuous belt dryer is well grounded to prevent personal safety due to leakage.

2. Operate the continuous tunnel furnace

(1) Start the conveyor dryer

Ar dtús, open the control electric box and the air switch.

Ar an dara dul síos, press the power button. Then directly operate the system on the computer. Turn on the conveyor and the conveyor belt starts to run. Next, start the wind motor. So centrifugal impleller fan starts to work.

Ar an tríú dul síos, set the working temperature of conveyor belt furnace. Enter the drying temperature directly on the computer. At the computer also shows the actual temperature in the tunnel oven.

Ina theannta sin, it can also set the belt conveyor speed on the computer. So customer can control the drying time.

(2) Shut down the continuous belt dryer

First, check whether all the products in the tunnel dryer out of the equipment.

Ar an dara dul síos, turn off the temperature control switches, from “ar” chun “off”

Ar an tríú dul síos, run empty for 10-15 nóiméad

Ansin, turn off the conveyor, wind motor and power supply in turn.

Faoi dheireadh, turn off the air switch and the main power supply.

chomh maith, if there is an emergency, you can press the emergency button.

3. Conveyor belt furnace maintenance

Press the buttons to lift the outer covers of the tunnel furnace. So you can fix the tunnel oven and exchange the heating lamps.

After a period of normal operation, the conveyor dryer needs frequent maintenance.

Customer can adjust the conveyor belt by the tensioning device. It can prevent deviation of oven conveyor belt.

Pay attention to keep the electric box clean. To avoid accumulation of dust, electrical short-circuit phenomenon occurs.

Lubricate the conveyor chain every week.

Freisin, always check the fixing bolts of the belt furnace and conveyor to prevent loosening.

CC

C1: Má úsáidimid an foirnéis crios iompair chun na codanna insteallta a thriomú, an athróidh sé an méid plaisteach?

A1: Má tá teocht triomú na foirnéise tolláin ard, athróidh sé méideanna an táirge. Ach le haghaidh páirteanna plaisteacha insteallta, de ghnáth ní bhíonn an teocht téimh ard, mar sin ní athraíonn sé méideanna plaisteacha.

C2: What’s the appplication of the continuous belt dryer?

A2: This industrial tunnel oven is special for drying pharmaceutical bottles. Ar ndóigh, this conveyor dryer can be also suitable for screen printing, cosmetic bottles, injection plastic parts, PCB, táirgí leictreonacha, srl.

C3: What is the drying time in continuous tunnel furnace?

A3: Our customer uses this conveyor belt furnace to dry pharmaceutical bottles for 16 minutes each time. Ar ndóigh, you can adjust the conveying speed to change the drying time.

C4: What is the difference between tray dryer and tunnel dryer?

A4: Tray dryer is suitable for small batch drying. But it’s not for big batch baking. Ag an am seo, it needs tunnel conveyor dryer.

Léirmheasanna

Níl aon léirmheasanna fós.