Beskrivelse

Dette er en skik tunnelovn tørreovn til en kunde. De bruger det til at tørre farmaceutiske flasker. Så dens opvarmningstemperatur er ikke høj (85℃). Det er en slags kontinuerlig remtørrer. (Selvfølgelig, Vi tilpasser normalt også transporttørrer ved høj temperatur). Den samlede længde af dette net bælteovn er 8.6 meter. Det har 6 opvarmningszoner. På hjørnet af tunneltørretumbleren, det er en 90 ° kurve PVC båndtransportør. Andet 2 transportmaskiner bruger teflonnetbæltet.

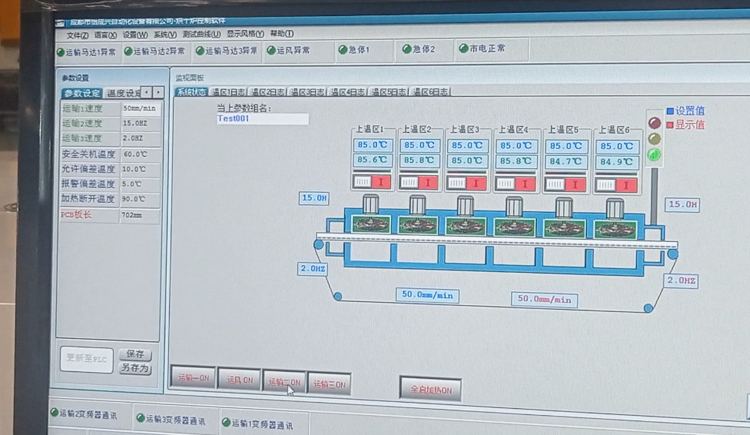

Det er en industriel infrarød transportørovn. Hver tørrezone har 6 stk IR varme rør. Ud over, denne kontinuerlige tunnelovn er et kontrolsystem. Kunden kan let betjene og styre maskebælteovnen på computeren.

Hvad er tunnelovnovn?

Det er en slags kontinuerlig remtørrer. Forskelligt fra tørreovn, det har transportør til at overføre produkterne. Så det behøver ikke, at folk flytter produkterne ofte. Fordi transportørens tørretumbler ligner en tunnel, det kaldes ofte tunnelovnen. Du kan bruge netbælttørretumbleren sammen med andre produktionssamlingslinjer. Så tunnelovn har mange egenskaber, såsom høj produktionseffektivitet, arbejdsbesparelse, og stabil bagekvalitet.

Denne tunnelovn består af teflonbåndtransportør, buet PVC båndtransportør, varmeovn og temperaturstyringssystem. for det første, produkterne kommer ind i bælteovnen fra indgangszonen. Derefter flytter transportbåndet produktet med den indstillede hastighed. Varmeelementet i transportørovnen tørrer produktet. Når tørringen er færdig, produkterne kommer ud af exitzonen.

Hvordan fungerer kontinuerlig tunnelovn?

På nuværende tidspunkt, varmluftcirkulation er en almindelig opvarmningsmetode for transportør tørretumbler. Det bruger princippet om konvektionskonduktion til opvarmning. Og varmeelementet vedtager de infrarøde varmelegemer. IR -varmerøret er placeret på transportørovnens øvre låg. Ud over, der er en ventilator i bælteovnen. Infrarød-sensing lyskilder kan skinne i hvert hjørne af bælteovnen. På samme tid, det interne varme luftcirkulationssystem fremmer en mere jævn temperatur inde i tunnelovnen. Ud over, aluminiumsilikatfibre fyldes mellem den indre foring og den ydre skal som et isoleringslag. Så isoleringsevne er god.

Hver arbejdsområde for kontinuerlig båndtørrer kontrolleres uafhængigt. På grund af termostaten, det kan styre temperaturen på transportbåndstunnelovnen i realtid. Og temperaturen tolerance for vores transportør tørretumbler kan nå ± 3 ℃.

Teknisk specifikation for kontinuerlig remtørrer

Below are the technical specifications of 6 heating zones tunnel furnace as above video. Selvfølgelig, we can customize the tunnel conveyor oven as customer’s requirements.

-

1. Mesh belt conveyor

- The conveyor consists of 2 sets of teflon mesh belt conveyor and 1 set of 90° curve conveyor. The belt width is 800mm. Under the mesh belt is a 1.5mm galvanized carrying plate with holes. Each conveyor uses 750W 3-phase motor with Delta brand VFD frequency converter. And conveying speed of the continuous belt dryer is 0~5 m/min adjustable.

The stands of conveyor belt furnace are 40*40mm painted carbon steel tubes. And there are height-adjustable feet. The mesh belt conveyor uses φ50mm driving and driven rollers. And curved conveyor uses cone rollers.

2. Heating oven

There are 6pcs of heating zones in this tunnel furnace. The outermost are outer convers for each oven. The material is painted carbon steel plate. The bracket can support the shell. Below the outer shell is the inner shell. The material is stainless steel plate. Ud over, there are electric push rods to lift the inner shells. So it is convenient for customers to repair the conveyor belt furnace. And the height of entrance area is 100mm.

Each conveyor oven uses 6pcs of infrared heater tubes. The IR heating tubes are installed on the stainless steel mirror plate. The wind motor is Taiwan brand 750W motor. And the impeller fan is connected to the wind motor. Centrifugal fan impleller can effectively promote the circulation of hot air in the furnace. Derudover, there are high temperature resistant sealing strips. So it can avoid heat escaping. The surface of tunnel furnace oven adopts white color powder-coating. And there are exhaust vents on continuous belt dryer.

3. Kontrolsystem

This continuous belt dryer has intelligent control system. So you can directly control the tunnel belt furnace on the computer. For eksempel, it can adjust the conveyor speed and drying temperature. It uses the RKC brand thermostat. Automatic constant temperature control. Other control circuit appliances adopt Chint Electric. Ud over, there are emergency control button, over-temperature power-off alarm, leakage protection, motor overload protection and other functions.

Operation instruction of continuous belt dryer

In order to protect the health and safety of end users, help users choose safe methods to operate the conveyor belt furnace. The use method and precautions of the tunnel furnace are as follows.

1. Installation and power distribution requirements

Adjust the feet to ensure that the conveyor dryer is level and stable.

Indgangseffekt: three-phase five-system, 380V, 50HZ/60HZ;

Maximum power: 54KW;

Power cord: three-phase five-wire, the power cord is not less than 6m㎡;

Ensure that continuous belt dryer is well grounded to prevent personal safety due to leakage.

2. Operate the continuous tunnel furnace

(1) Start the conveyor dryer

for det første, open the control electric box and the air switch.

For det andet, press the power button. Then directly operate the system on the computer. Turn on the conveyor and the conveyor belt starts to run. Næste, start the wind motor. So centrifugal impleller fan starts to work.

For det tredje, set the working temperature of conveyor belt furnace. Enter the drying temperature directly on the computer. At the computer also shows the actual temperature in the tunnel oven.

Derudover, it can also set the belt conveyor speed on the computer. So customer can control the drying time.

(2) Shut down the continuous belt dryer

Først, check whether all the products in the tunnel dryer out of the equipment.

For det andet, turn off the temperature control switches, from “på” til “af”

For det tredje, run empty for 10-15 minutter

Derefter, turn off the conveyor, wind motor and power supply in turn.

Endelig, turn off the air switch and the main power supply.

Derudover, hvis der er en nødsituation, you can press the emergency button.

3. Conveyor belt furnace maintenance

Press the buttons to lift the outer covers of the tunnel furnace. So you can fix the tunnel oven and exchange the heating lamps.

After a period of normal operation, the conveyor dryer needs frequent maintenance.

Customer can adjust the conveyor belt by the tensioning device. It can prevent deviation of oven conveyor belt.

Pay attention to keep the electric box clean. To avoid accumulation of dust, electrical short-circuit phenomenon occurs.

Lubricate the conveyor chain every week.

Ud over, always check the fixing bolts of the belt furnace and conveyor to prevent loosening.

Ofte stillede spørgsmål

Q1: Hvis vi bruger transportbåndsovnen til at tørre injektionsdelene, vil det ændre plaststørrelsen?

A1: Hvis tørretemperaturen i tunnelovnen er høj, det vil ændre produktstørrelser. Men til indsprøjtning af plastdele, opvarmningstemperaturen er normalt ikke høj, så det ændrer ikke plaststørrelser.

Q2: What’s the appplication of the continuous belt dryer?

A2: This industrial tunnel oven is special for drying pharmaceutical bottles. Selvfølgelig, this conveyor dryer can be also suitable for screen printing, tunneltørrer med transportør har flere anvendelsesmuligheder, injection plastic parts, PCB, elektroniske produkter, etc.

Q3: What is the drying time in continuous tunnel furnace?

A3: Our customer uses this conveyor belt furnace to dry pharmaceutical bottles for 16 minutes each time. Selvfølgelig, you can adjust the conveying speed to change the drying time.

Q4: Hvad er forskellen mellem bakketørrer og tunneltørrer?

A4: Tray dryer is suitable for small batch drying. But it’s not for big batch baking. På dette tidspunkt, it needs tunnel conveyor dryer.

Anmeldelser

Der er ingen bedømmelser endnu.