Opis

Ovo je običaj tunelska peć sušara za klijenta. Koriste ga za sušenje boca s lijekovima. Dakle, njegova temperatura grijanja nije visoka (85℃). To je neka vrsta kontinualna tračna sušilica. (Naravno, obično obično prilagođavamo i sušilicu za transport na visokim temperaturama). Ukupna dužina ove mreže kaišna peć je 8.6 metara. Ima 6 zone grijanja. Na uglu tunelske sušare, radi se o 90 ° zavojitom PVC trakastom transporteru. Ostalo 2 transportne mašine koriste teflonsku mrežastu traku.

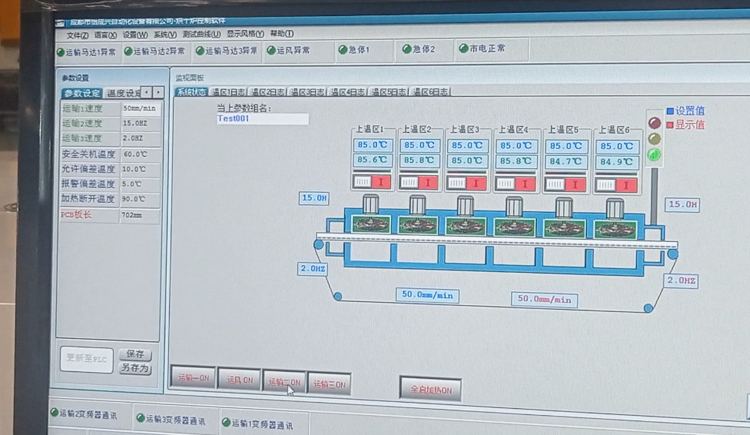

To je industrijska infracrvena transportna pećnica. Svaka zona sušenja ima 6 kom IR cijevi za grijanje. Pored toga, ova kontinualna tunelska peć je sistem upravljanja. Kupac može lako upravljati i upravljati mrežnom peći na računaru.

Šta je tunelska peć?

To je neka vrsta trajnog sušača za traku. Za razliku od pećnice za sušenje, ima transporter za prenos proizvoda. Dakle, nije potrebno da ljudi često premještaju proizvode. Zato što transportna sušilica izgleda kao tunel, često se naziva tunelska peć. Mrežastu traku za sušenje možete koristiti zajedno s drugim proizvodnim linijama za montažu. Dakle, tunelska peć ima mnoge karakteristike, kao što je visoka efikasnost proizvodnje, ušteda radne snage, i stabilan kvalitet pečenja.

Ova tunelska pećnica sastoji se od teflonske trake, zakrivljeni transportni trak od PVC -a, grejanje peći i sistem za kontrolu temperature. Prvo, proizvodi ulaze u trakastu peć iz ulazne zone. Zatim transportna traka pomiče proizvod zadanom brzinom. Grijaći element u transportnoj pećnici osuši proizvod. Kad se sušenje završi, proizvodi izlaze iz izlazne zone.

Kako radi kontinuirana tunelska peć??

Trenutno, cirkulacija toplog zraka uobičajena je metoda grijanja za transportne sušilice. Za zagrijavanje koristi princip konvekcijske provodljivosti. I grijaći element prihvaća infracrvene grijaće cijevi. IR cijev za grijanje nalazi se na gornjem poklopcu transportne pećnice. Pored toga, postoji ventilator u kaišnoj peći. Izvori svjetlosti s infracrvenim zračenjem mogu zasjati u svakom kutu tračne peći. U isto vrijeme, unutrašnji sistem cirkulacije toplog vazduha promoviše ravnomerniju temperaturu unutar tunelske peći. Pored toga, aluminijsko silikatno vlakno ispunjeno je između unutarnje obloge i vanjske ljuske kao izolacijski sloj. Dakle, performanse izolacije su dobre.

Svaka radna zona kontinuirane tračne sušilice nezavisno se kontroliše. Zbog termostata, može kontrolirati temperaturu tunelske pećnice u stvarnom vremenu. Tolerancija temperature naše transportne sušilice može doseći ± 3 ℃.

Tehničke specifikacije kontinuirane tračne sušilice

Below are the technical specifications of 6 heating zones tunnel furnace as above video. Naravno, we can customize the tunnel conveyor oven as customer’s requirements.

-

1. Mesh belt conveyor

- The conveyor consists of 2 sets of teflon mesh belt conveyor and 1 set of 90° curve conveyor. The belt width is 800mm. Under the mesh belt is a 1.5mm galvanized carrying plate with holes. Each conveyor uses 750W 3-phase motor with Delta brand VFD frequency converter. And conveying speed of the continuous belt dryer is 0~5 m/min adjustable.

The stands of conveyor belt furnace are 40*40mm painted carbon steel tubes. And there are height-adjustable feet. The mesh belt conveyor uses φ50mm driving and driven rollers. And curved conveyor uses cone rollers.

2. Heating oven

There are 6pcs of heating zones in this tunnel furnace. The outermost are outer convers for each oven. The material is painted carbon steel plate. The bracket can support the shell. Below the outer shell is the inner shell. The material is stainless steel plate. Pored toga, there are electric push rods to lift the inner shells. So it is convenient for customers to repair the conveyor belt furnace. And the height of entrance area is 100mm.

Each conveyor oven uses 6pcs of infrared heater tubes. The IR heating tubes are installed on the stainless steel mirror plate. The wind motor is Taiwan brand 750W motor. And the impeller fan is connected to the wind motor. Centrifugal fan impleller can effectively promote the circulation of hot air in the furnace. Dodatno, there are high temperature resistant sealing strips. So it can avoid heat escaping. The surface of tunnel furnace oven adopts white color powder-coating. And there are exhaust vents on continuous belt dryer.

3. Sistem kontrole

This continuous belt dryer has intelligent control system. So you can directly control the tunnel belt furnace on the computer. Na primjer, it can adjust the conveyor speed and drying temperature. It uses the RKC brand thermostat. Automatic constant temperature control. Other control circuit appliances adopt Chint Electric. Pored toga, there are emergency control button, over-temperature power-off alarm, leakage protection, motor overload protection and other functions.

Operation instruction of continuous belt dryer

In order to protect the health and safety of end users, help users choose safe methods to operate the conveyor belt furnace. The use method and precautions of the tunnel furnace are as follows.

1. Installation and power distribution requirements

Adjust the feet to ensure that the conveyor dryer is level and stable.

Input power: three-phase five-system, 380V, 50HZ/60HZ;

Maximum power: 54KW;

Power cord: three-phase five-wire, the power cord is not less than 6m㎡;

Ensure that continuous belt dryer is well grounded to prevent personal safety due to leakage.

2. Operate the continuous tunnel furnace

(1) Start the conveyor dryer

Prvo, open the control electric box and the air switch.

Drugo, press the power button. Then directly operate the system on the computer. Turn on the conveyor and the conveyor belt starts to run. Sljedeći, start the wind motor. So centrifugal impleller fan starts to work.

Treće, set the working temperature of conveyor belt furnace. Enter the drying temperature directly on the computer. At the computer also shows the actual temperature in the tunnel oven.

In addtion, it can also set the belt conveyor speed on the computer. So customer can control the drying time.

(2) Shut down the continuous belt dryer

Prvo, check whether all the products in the tunnel dryer out of the equipment.

Drugo, turn off the temperature control switches, from “on” to “off”

Treće, run empty for 10-15 minuta

Onda, turn off the conveyor, wind motor and power supply in turn.

Konačno, turn off the air switch and the main power supply.

Dodatno, ako postoji hitan slučaj, you can press the emergency button.

3. Conveyor belt furnace maintenance

Press the buttons to lift the outer covers of the tunnel furnace. So you can fix the tunnel oven and exchange the heating lamps.

After a period of normal operation, the conveyor dryer needs frequent maintenance.

Customer can adjust the conveyor belt by the tensioning device. It can prevent deviation of oven conveyor belt.

Pay attention to keep the electric box clean. To avoid accumulation of dust, electrical short-circuit phenomenon occurs.

Lubricate the conveyor chain every week.

Pored toga, always check the fixing bolts of the belt furnace and conveyor to prevent loosening.

FAQ

Q1: Ako za sušenje dijelova za ubrizgavanje koristimo peć s transportnom trakom, hoće li promijeniti veličinu plastike?

A1: Ako je temperatura sušenja tunelske peći visoka, to će promijeniti veličinu proizvoda. Ali za ubrizgavanje plastičnih dijelova, temperatura grijanja obično nije visoka, tako da ne mijenja veličine plastike.

Q2: What’s the appplication of the continuous belt dryer?

A2: This industrial tunnel oven is special for drying pharmaceutical bottles. Naravno, this conveyor dryer can be also suitable for screen printing, kozmetičke boce, injection plastic parts, PCB, elektronski proizvodi, itd.

Q3: What is the drying time in continuous tunnel furnace?

A3: Our customer uses this conveyor belt furnace to dry pharmaceutical bottles for 16 minutes each time. Naravno, you can adjust the conveying speed to change the drying time.

Q4: Koja je razlika između tacne i tunelske sušilice?

A4: Tray dryer is suitable for small batch drying. But it’s not for big batch baking. U ovom trenutku, it needs tunnel conveyor dryer.

Recenzije

Još nema recenzija.