Opis

Transportni sistem montažne linije je važna oprema proizvodne linije. Poprečni transporter slobodnog protoka usvaja dvostruki brzi lanac kao vučni nosač. Paleta obratka može se slobodno transportovati. Odabire položaj čepa, tako da se obradak može slobodno kretati ili zaustavljati. Dizajn transportera paleta obratka je fleksibilan. A funkcije su raznolike. Dvobrzinski lančani transporter ima široku primjenu u industriji montaže, kao što su elektronički uređaji i elektromehanička industrija.

Tehničke specifikacije transportnog sistema montažne linije

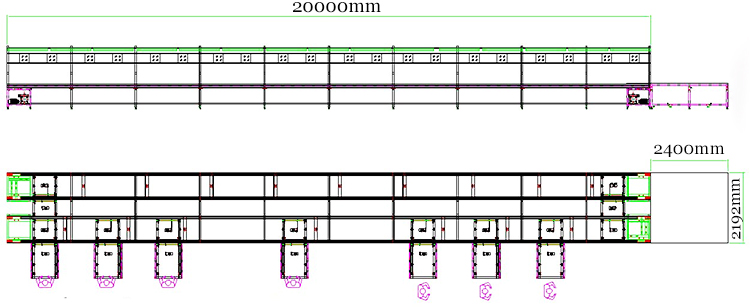

Ovdje navodimo primjer kružnog transportnog transportera od 20 metara za kupca stroja za zavarivanje.

| Ne. | Ime | Specifikacija montažnog transportera | Ne |

| Circular Assembly Line for Welder | 20 meters(L20m*W1950mm*H1.880m) | 1 set | |

| 1 | Pogonski sistem |

|

2 set |

| 2 | Frame of Assembly Line Conveyor System | 1. The support stands use 50mm * 50mm * 2.mm square tubes; 2. The guide rails of transverse conveyor super-strength 100*118mm special triple-speed aluminum profiles; 3. It adopts T5 18W single LED lamp with cover; 4. Install two-position plug-in seats at each workstation, each 1.2m/set; 5. Assemble the pneumatic triplet parts 40SM with 20PH quick connector; |

40 m |

| 3 | Control Box | Korištenje Mitsubishi PLC kontrole, Mitsubishi prekidač za zrak i OMRON relej (Dostupne su i druge marke) |

1 set |

| 4 | Paleta obratka | 1. Veličina: L(800)*W(800)*T(20) (mm); 2. Paleta obratka izrađena je od drveta od 20 mm. Pored toga, dvoslojni kružni rotacijski slobodni prijelaz. Osim toga na površini je zelena antistatička guma; |

36 kom |

| 5 | Blocker | DY-1 visokokvalitetni blokator opremljen pneumatskim prekidačem nožne pedale; | 34 setovi |

| 6 | Uređaj za podizanje i prenošenje za alatnu ploču | 1. Motor Toho 60W pokreće sinhroni transportni trak; 2. Cilindar je sa dvopolnim petosmjernim magnetnim ventilom za podizanje; 3. Usvaja OMRON putni prekidač. |

11 setovi |

| 7 | Prijelazni uređaj za prijenos | 1. Toho 60W sinhroni trakasti transporter sa motorom; 2. It adopts OMRON travel switch and SKK electric eye. |

2 setovi |

| 8 | ESD Workbench | 1000*1000*800mm | 7 setovi |

| 9 | Probni ormar za zavarivanje | 1000*500*1500mm | 2 setovi |

| 10 | Kabinet za kontrolu puštanja u rad | 550*550*1500mm | 7 setovi |

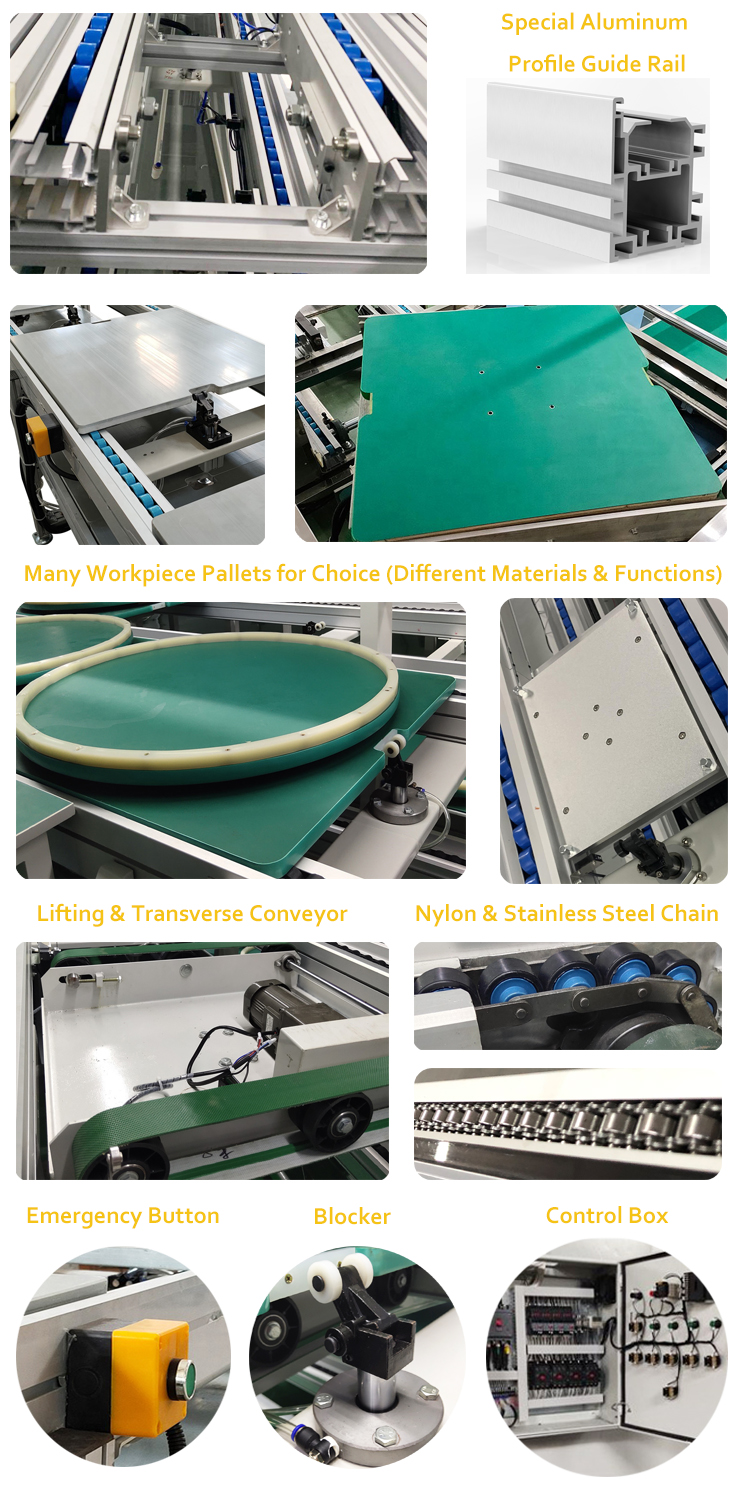

Detalji & Karakteristike našeg transverzalnog transportera za palete obratka

1. Prvo, the double-speed chain conveyor uses a special aluminum profile guide rails. It is different from other conveyor rails.

2. Drugo, the workpiece pallet can be customizable according to the specific production process. There are different loads and material choices, such as wood, PVC, aluminum, odrediti vrstu lanca sa dvostrukom brzinom, itd.

3. Treće, the lifting and transverse conveyor can help realize the circular assembly line. It is determined by the size of the workpiece pallet. U normalnim okolnostima, a horizontal circular assembly conveyor line requires 4 sets of traverse conveyors.

4. Slično, the accumulation roller chain also has a distinction between load and material. There are light load and heavy load free flow conveyor chains. Pored toga, there are nylon, carbon steel and stainless steel materials.

5. The blocking mechanism can block the tooling board. The product is processed in the relevant process at this workstation. Release after processing.

6. In case of emergencies, press the emergency button firstly. Then check the assembly line conveyor system.

How to operate the free flow chain assembly line conveyor system?

1. Prvo, turn on the compressed air switch. After the gas storage tank pressure reaches 5KG, turn on the gas valve switch to inflate the conveyor assembly line.

2. Drugo, turn on the power switch on the panel of the electric control box. U ovom trenutku, lampica indikatora napajanja je uključena. The VFD is energized. Adjust the motor speed according to the production cycle requirements. Onda, twist the selection mode switch. Choose the mode you want to run. Sljedeći, activate the run switch. Then the assembly line conveyor system will run automatically.

3. Treće, check whether the lifting and transverse conveyor is lowered in place when there is no workpiece pallet. If not, reset it manually. To je, turn on the manual switch of this conveyor. Then press down manually. Finally reset to the automatic switch.

4. Četvrto, check whether the lifting and transverse conveyor has risen in place when starting up. If not, follow the same method as above.

5. Na primjer, the assembly line conveyor is designed for free rhythm. Each station is set to free-release mode according to the production cycle.

6. Konačno, the shutdown operation: turn off the socket power supply, turn off the lighting switch, turn off the air source, and turn off the master switch.

If you want to customize the sistem transportne trake za montažu, pls contact us.

Recenzije

Još nema recenzija.