顯示全部 5 結果

裝配輸送機係一種生產線輸送系統. 裝配線輸送系統集成多種功能, 如輸送, 定位, 停止, 提升, 旋轉, 把, 控制, 等. 因此, 理想嘅自動化生產設備. 喺工業產品組裝中具有廣泛嘅應用, 如電子, 汽車安全座椅, 家電, 鋰電池, 半導體, 金屬零件, 模具, 工件, 等.

作為裝配輸送機製造商, 我哋可以定製三種輸送機生產線. 這就說, 工件托盘輸送系統, 自由流動鏈式輸送機和生產線輸送帶. 其中, 前兩條係自動化裝配線. 最後一個係 手動裝配線. 另外, 有橫線組成, 縱向和您根據形狀塑造生產線.

-

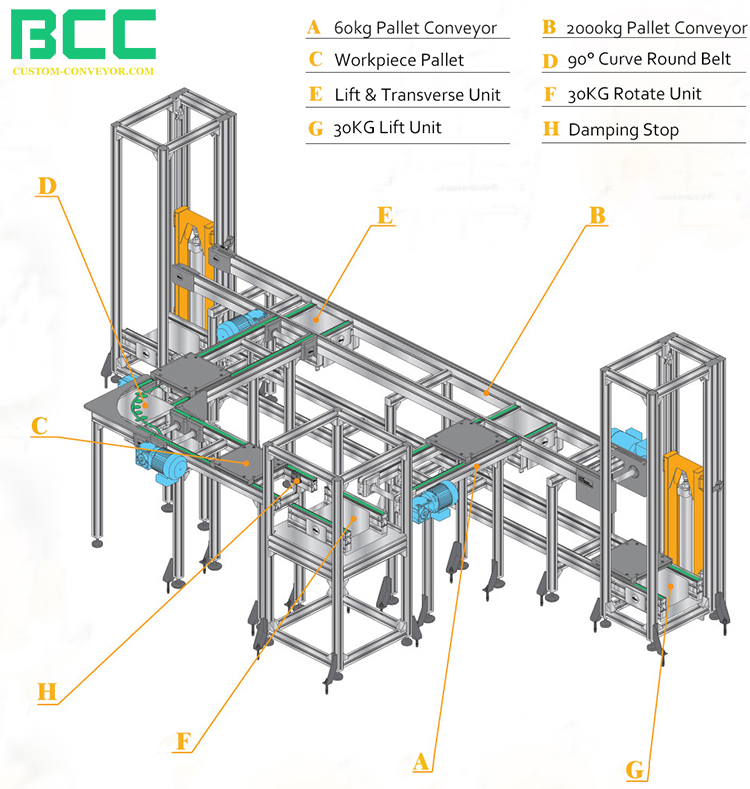

1. 糢塊化工件托盘裝配輸送系統

-

(1) 乜嘢係糢塊化工件托盘輸送機?

- 講真, 佢係一種糢塊化裝配線. 我哋嘅工件輸送機類似于博世TS托盘輸送機. 它包括橫向輸送機和縱向輸送機. 此外, 不同重量的有效載荷有多種類型, 由幾公斤到2000公斤.

糢塊化工件托盘裝配輸送系統係一種工裝板傳送平台. 適用於物料搬運, 產品組裝和測試, 等. 因此可以滿足各種工業自動化生產嘅要求.

工件托盘裝配輸送機嘅應用

- 機電行業生產線,

電子裝配線,

電腦顯示器生產線,

電腦大型機生產線,

筆記本電腦裝配綫,

空調生產線,

電視組裝線,

微波爐裝配線, - 打印機裝配線,

音頻放大器生產線,

發動機裝配線,

螺絲機裝配線,

點膠機裝配線,

焊錫機流水綫,

模具裝配線,

汽車座椅裝配線,

金屬零件裝配線.

(2) 托盘輸送輸送系統技術參數

|

輸送 |

輸送介質 |

輸送機長度 |

托盘尺寸 |

麥克斯 |

麥克斯. 輸送機速度 |

|

PTS1 |

齒形帶 |

400≤L≤6000 |

160≤Bwt≤400 |

60 |

20 |

|

PTS1/H |

尼龍帶 |

1200≤L≤12000 |

160≤BWT≤640 |

160 |

20 |

|

PTS2 |

積累 滾子鏈 |

600≤L≤ 12000 |

160≤Bwt≤800 |

1000 |

20 |

|

PTS4 |

積累 滾子鏈 |

1000≤L≤ 18000 |

400≤Bwt≤1200 |

2500 |

20 |

|

PTS5 |

輗 |

1000≤ L≤ 6000 |

300≤Bwt≤1200 |

4500 |

15 |

(3) 工件托盘輸送機嘅類型

托盘輸送機系統適用於多種工業生產過程. 我哋可以用它嚟建立加工中嘅自動工件流解決方案, 集會, 同測試流程. 除了標準輸送機糢塊外,仲可以快速輕鬆地創建簡單同高級嘅佈線布局, 平衡, 托盘嘅緩衝同定位.

工件托盘輸送機嘅尺寸同負載能力不同. 托盘傳輸系統由標準化組件組成. 因此, 它可以組合不同的單元以滿足特定的自動化要求. 我哋通常定製 4 基於工件托盘嘅輸送機系統嘅類型. 這就說, 定時 (齒) 帶式輸送機, 尼龍帶式輸送機, 堆積輗鏈輸送機和滾筒工件輸送機.

-

1) 同步帶式輸送機,最大有效載荷可達60KG

- 呢種糢塊化裝配線輸送機使用齒形同步帶. 所以它的承載能力唔高. 請注意,60KG係其總承重能力, 唔係單個工件託槃嘅負載. 單工件托盤承重能力為15KG.

糢塊化工作托盘總成同步帶式輸送機技術參數

工件輸送機長度: 220~6000毫米;

裝配輸送系統嘅負載能力: 0~60公斤;

輸送速度: 5±20m/分鐘;

工件托盘尺寸: 160, 240, 320, 400, 480 同640毫米;

支架間距距離: 800~1600毫米;

輸送介質為抗靜電齒形帶;

電機安裝類型: 端驅或中心傳動.

同步帶托盘總成輸送機嘅特點

(1)適用於輕載場合的輸送;

(2)由於糢塊化設計, 易於安裝和維護;

( 3 )由於使用鋁合金框架, 安裝其他配件好方便, 如傳感器, 緩衝區, 等.

(4)易於實現累積功能. 因為它與起重機械配合使用, 圓帶車床, 吊裝橫移機等部件, 可實現自動循環輸送.

(5)本輸送機裝配線靈活, 乾淨, 穩定, 低噪音, 壽命長.

2) 糢塊化尼龍帶裝配托盘輸送機,最大有效載荷可達160KG

呢種尼龍基帶式輸送機比第一種具有更高嘅負載能力. 最大承重160KG.

該裝配輸送機系統嘅技術參數:

工件托盘裝配輸送機最大負載能力: 160公斤;

該流水綫輸送機嘅長度: 600~12000毫米;

工件托盘尺寸: 160毫米~640毫米;

輸送機速度: 5±20m/分鐘;

輸送介質: 尼龙基帶;

驅動類型: 直接驅動, 電機可以喺末端或中心;

親切嘅筆記:

1載荷係流水綫輸送機嘅總載荷. 單位負載能力為≤0.6公斤/厘米.

(2)默認平帶為寬度為30mm的防靜電基帶.

尼龍帶式托盘輸送系統嘅特點

(1)模塊化設計,可快速組裝. 同時, 便於後續維護.

(2)適用於小件貨物嘅長途運輸.

(3)方便實現累積功能. 此外, 與其他組件, 如起重 & 定位, 可實現超高柔性設計.

(4)裝配線輸送機需要與我們的托盤一起使用. 如果唔使用我哋嘅托盘, 你需要與我哋公司確認才能使用。.

(5)裝配輸送系統需要根據輸送方向輸送物體. 禁止反向輸送.

(6)輸送機機架採用鋁型材. 因此, 它可以快速連接外部設備. 以便您可以快速安裝輸送機生產線.

( 7 )嚴禁托盘上嘅金屬或尖銳物體直接接觸摩擦皮帶. 否則, 傳送帶會磨損或快速斷裂.

3) 模塊化堆積滾子鏈輸送機~3種有效載荷至200KG, 500公斤 & 2000公斤

與上述輸送機裝配線相比, 該輸送機系統具有更高嘅負載能力. 此外, 該輸送機生產線使用堆積滾子鏈作為輸送介質. 現時, 我哋設計咗三種類型嘅托盘鏈輸送機,以適應不同的負載要求.

堆積滾子鏈裝配線輸送機技術規格

輸送機負載能力: 三種~200KG, 500KG同2000KG;

糢塊化裝配線長度: 最大2000mm,負載200KG, 最大10000mm為500kg & 2000公斤負載;

工件托盘輸送機速度: 最大20米/分鐘;

工件托盘尺寸: 160~640毫米;

輸送介質: 累積滾子鏈 (滾筒材料可以係尼龍同鋼).

親切嘅筆記:

(1) 200KG & 500KG負載裝配線輸送機, 單位負載能力為≤1.2公斤/厘米;

用于2000KG負載糢塊化托盘輸送機, 單位負載能力為≤2.0公斤/厘米.

(2)鏈條採用耐用的不銹鋼鏈條.

托盘鏈裝配綫輸送機嘅特點

(1)適用於介質的貨物轉運 & 高負載, 如發動機, 汽車零件, 模具, 等;

(2)本托盤輸送機採用鋁型材和不銹鋼鏈條. 所以結構穩定. 此外, 安裝方便.

3流水綫輸送機設計可以非常靈活. 例如, 如果你想實現轉彎功能, 可快速添加曲線輸送機. 因此它可以成為圓形裝配輸送系統.

(4)由于使用了累積滾子鏈, 托盘傳輸系統噪音低,經濟實惠.

(5)與普通輸送機相比, 它不能雙向輸送工件. 工件托盘只能朝向電機移動.

(4) 糢塊化托盘裝配線輸送機布局

點解需要糢塊化托盘裝配線輸送機? 最大嘅原因係它的設計和布局非常靈活. 例如, 我哋只需要添加相應嘅組件即可實現改變輸送方向等各種功能, 暫停, 同旋轉. 為咗了解輸送機嘅布局, 我哋首先需要了解相關嘅功能部件.

-

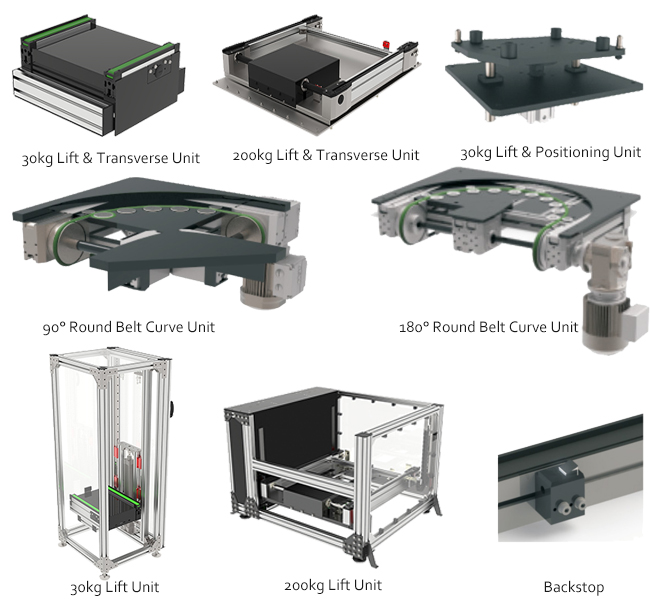

1) 托盘傳輸系統嘅組成部分

(1)30公斤舉重 & 橫向單位功能:

首先, 可實現圓形流水綫輸送機喺拐角处嘅橫向移動. 同時, 仲可以實現支線嘅橫向移動.

当需要橫向提升和移動工件托盘時, 停止並執行提升和水平移動. 如果託槃唔需要轉移, 設備保持原來的低位,以便托盘可以直接通過.

最後, ITT可以實現分流同匯合嘅功能.

(2)200公斤舉重 & 橫向單元特點 & 功能:

講真, 與上述30kg單元具有相似的功能. 糢塊化設計, 實用性強.

它可以改變托盘嘅輸送方向. 例如, 該設備可以把托盘橫向移動到另一台裝配線輸送機.

最後, 它採用高強度鋁型材框架. 因此,把本機安裝到裝配輸送機系統上好方便. 此外, 安裝其他配件都好易.

(3)30公斤升降機 & 定位單位特點 & 功能:

組件透過定位銷和托盘銷一起實現定位功能;

初始定位高度根據選擇適應裝配輸送機類型嘅變化;

它適用於我哋所有嘅糢塊化托盘輸送機同撐托盘.

(4)90°曲線圓帶單元特點 & 功能:

首先, 可實現工件托盘90°旋轉. 並且唔會改變托盘嘅輸送方向. 因此,它可以幫助實現圓形流水綫輸送機.

其次, 該曲線糢塊托盘輸送機單獨配備電機;

第三, 輸送託槃嘅縱橫比不能超過 1.5.

最後, 該旋轉機構一次只能透過一個託槃. 禁止堆放託槃.

(5)180°曲線圓帶單元特點 & 功能:

首先 ,該托盘傳輸糢塊可以令托盘以180°旋轉.

另外, 其他功能與上述90°曲線單元相同.

(6)30kg提升裝置特點 & 功能:

該升降機利用氣缸實現升降功能. 因此可以實現高低流水線輸送機之間嘅垂直循環.

輸送介質為齒形帶. 因此, 該升降機適用於輕載場合.

電梯配有止囘閥. 因此可以防止空氣被切斷時托盘突然掉落. 因此, 確保裝配輸送系統嘅安全性.

(7)200kg提升裝置特點 & 功能:

首先, 該升降機適用於單個託盤滿載喺200KG以內嘅輸送場合.

其次, 不同於上述30公斤嘅舉重運動員, 輸送介質為標準鏈條或08BS堆積滾子鏈.

因為佢係糢塊化設計嘅獨立組件, 便於安裝到流水線輸送系統中.

同樣地, 仲可以實現工件托盘嘅垂直循環.

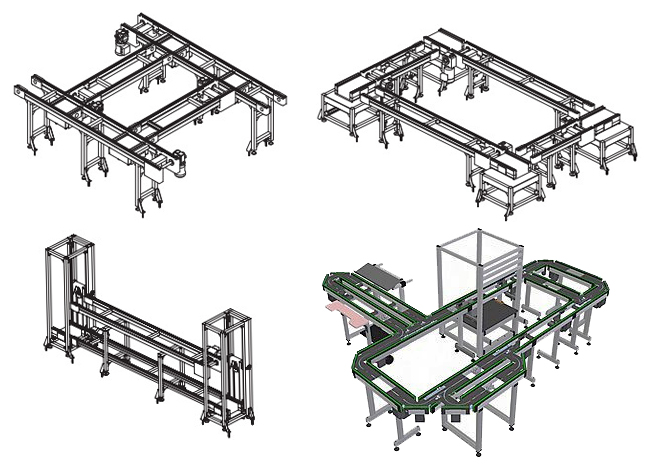

2) 裝配輸送機系統布局

因為有多個功能組件, 可以安裝各種形狀和布局嘅裝配輸送系統. 此外, 呢啲組件採用糢塊化設計. 因此,流水綫輸送機布局可以非常靈活多樣.

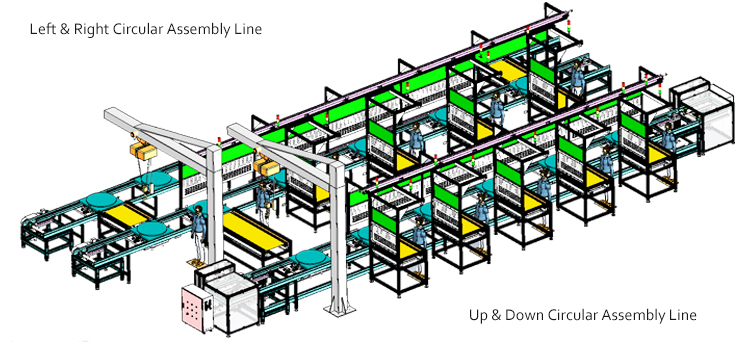

例如, 由於升降橫單位同曲線裝置, 可輕鬆搭建水平循環裝配生產線. 此外, 它可以使用升降機快速構建垂直輸送系統. 它們是兩種最常見的裝配輸送機佈局. 答案係肯定嘅, 它仲可以根據需要組裝更複雜嘅生產線輸送系統.

橫向輸送機和縱向輸送機用于匹配全自動過程. 佢哋使用特殊嘅工具板嚟匹配應用. 定位精度高. 好多自動化生產過程都使用糢塊化裝配線輸送機. 例如, 配藥, 固化, 自動螺釘鎖定, 鉚, 沖壓, 焊接, 等.

(5) 如何安裝糢塊化托盘流水綫輸送機?

由於它們都係糢塊化設計, 它們安裝起來非常方便. 您可以根據裝配輸送機安裝說明輕鬆完成操作. If you receive the conveyor machine in parts or units, please follow the below assembly instructions.

另外, due to the similar structure of several modular pallet conveyors, here we mainly explain the installation of chain assembly line conveyors.

步 1, assemble the frame of modular pallet conveyor.

Assemble the conveyor stands and put them to the layout position. And then mount the guide rails onto the support legs. 最後, it needs to adjust the foot to ensure same height of stands.

步 2, install the drive unit and driven unit

It is similar to 塑料鏈輸送機. This modular pallet chain assembly line conveyor also include drive unit and driven unit. Install them onto the guide rails. 答案係肯定嘅, the motor installation position can be at end or in the middle as needs.

步 3, assemble the accumulating roller chain

This installation step is relatively more complicated. 下一個, I will explain how to install the accumulating roller chain on the conveyor assembly line.

1首先, put the conveyor chain on the chain shaft. It can avoid chain damage from twisting during the chain installation process.

(2)其次, guide one end of chain with a fine steel wire. Let the chain go along the lower part of drive unit. And then go trough lower part of assembly conveyor. 隨即, bypass the driven sprocket of the driven unit. Finally connect the ends of the chain with chain slipknot.

③ Similar to 小型輸送帶, it needs to adjust the chain tension after installation. Otherwise it will affect the load capacity of the assembly line conveyor. 同時, it also affect normal operation.

步 4, install other components or accessories

Put the workpiece pallets onto the assembly conveyor system. 另外, our modular assembly line usually have other accesories, such as damper and return stop. It usually mount them onto the guide rails with screws.

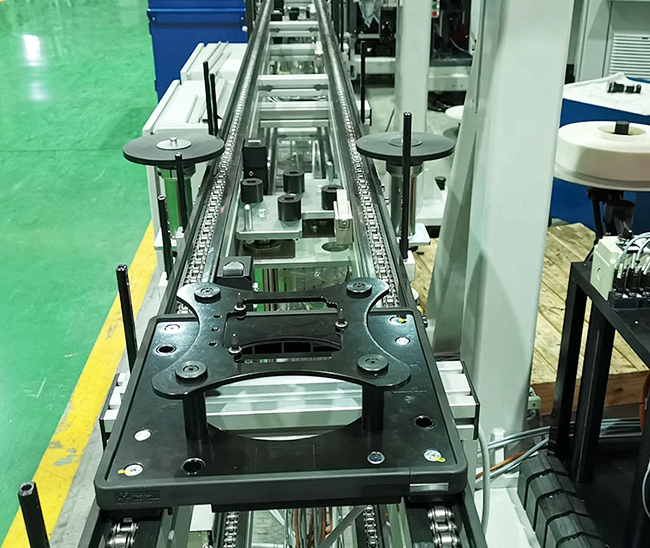

2. Free Flow Conveyor Assembly Line

Free flow chain conveyor is also a common automated assembly production line. 講真, this conveyor is very similar to the above accumulating roller chain conveyor. Both of them use the accumulating roller chain as the conveying medium. 此外, there are also two types: horizontal and vertical circular assembly line. There are also the components, such as lift & transverse unit and blocker.

But there are also some differences. 首先, free flow chain conveyor has more complicated structure. It’s often equipped with ESD workbenches and light stands. 此外, the structure of lift & transverse unit and blocker is a bit different. 另外, the length of free flow chain conveyor can be longer. It can reach 30m.

What is free flow chain conveyor?

It is also namely accumulating roller conveyor or double-speed chain conveyor. As the name implies, the conveying speed of the tooling plate is greater than the transmission speed of the chain. Besides it’s twice or three times the transmission speed.

因此, the tooling plate supporting the workpieces on the chain can move quickly. 另外, the blocker can stop the tooling board at the corresponding operating position. The tooling plate can rotate. And it can achieve accumulation by corresponding instructions. Because of its high-efficiency conveying effect, it becomes very popular.

Characteristics of free flow conveyor assembly line

1) The conveyor uses roller chains as the transfer medium. The roller is in direct contact with the track. 此外, the rotation of the roller forms the transmission of the product on the roller. So it can achieve accumulating functin.

2) Aluminum profile acts as guide rails. So it make the entire assembly conveyor system have high stability and durability. 此外, it can carry a heavy load. 同時, it can achieve long conveying distance.

3) Beautiful structure, 低噪音, diversified functions and high degree of automation.

結構 & Technical Specification of Free Flow Chain Conveyor

The form below is an example of a 30-meter assembly line conveyor made for a customer.

|

唔係. |

Parts Name |

Technical Specification |

|

1 |

Drive System |

① Taiwan Brand 3HP Horizontal motor; ② Speed of workpiece pallet: 6米/分鐘; ③ The transportation of tooling board uses RF2060, 3 times speed chain.. |

|

2 |

Frame Structure |

① The bracket adopts 50mm*50mm*2.0mm square tube. The height of the working surface: 740±20. The workbench surface is pasted with anti-static rubber. ② The guide rails on both sides of the assembly line conveyor use 100*118mm aluminum profile. ③ The lighting uses T5 18W single LED lamp with cover. 另外, the light support frame uses 20*40 iron tube; |

|

3 |

Control System |

① Controlled by Mitsubishi PLC; ② Mitsubishi Air Switch; ③ OMRON relay. |

|

4 |

Tooling Plate |

① Size (毫米): (850)L*(850)W*(20)T; ② The tooling board uses 20mm splint plate. The double-layer round structure, and rotates freely for transition. The surface is pasted with green anti-static rubber. |

|

5 |

Blocker |

QX-3 high-quality blocker with foot switch control |

|

6 |

升ift & Transverse Unit |

① Taiwan brand 60W motor, driving timing belt conveyor; ② Cylinder with two-position five-way solenoid valve for lifting; ③ The control adopts OMRON travel switch. |

|

7 |

Workbench |

① Size: 600*400*750毫米; ② The independent workbench stands use 30*30mm square tubes. The worktop is made of 18mm wood plate. 此外,表面粘貼有綠色防靜電橡膠. |

3. Manual Assembly Line Belt Conveyor

有時, we don’t necessarily need a fully automated assembly conveyor. So it can choose the manufal assembly line. The most common is the assembly line table. 講真, it also contains several types according to needs and structures. 答案係肯定嘅, it mainly composes of belt conveyor and ESD workbench.

What is manual assembly line?

It is also called assembly line workbench. It is an equipment that can improve work efficiency. 同時, these work needs a lot of manpower. According to the operating speed of the personnel, it can adjust product conveying speed. And it can realize continuous assembly production.

It usually also uses aluminum profile as the frame. At the same time there is a belt conveyor in the middle. There are anti-static workbenches on both sides to facilitate workers to assemble products.

Features of Manual Assembly Line Belt Conveyor

① It adopts assembly line operation, so it can greatly improve production efficiency;

② Use standard materials and accessories to assemble. Thus the structure is simple and the application is flexible.

③ Simple modification. You can expand the structure function at any time as needed. Especially sometimes it can add the frame structural parts at will without disassembly.

④ Finally the materials can be reused. You can reuse aluminum profiles and other accessories. So save production costs. This assembly line conveyor is environmentally friendly.

4. How to choose the right assembly line conveyor system?

Industry is now developing rapidly. 因此, all industries have higher and higher requirements for production efficiency. Whether you produce electronic products or car seats, it needs assembly line. So what is the best assembly conveyor system? 講真, this is not only a technical issue, but also an economic issue.

(1) Automated vs manual ?

Different countries, different situations. In developing countries, labor costs are relatively low. The initial investment of automatic production lines is generally very large. So many enterprises usually choose the manual assembly line. The investment in the manual assembly line is much smaller. Companies can often recover costs quickly.

例如, it has wide application in the home appliance and electronic industries. At the beginning of the 21st century, these industries were very common in China. Because labor costs were low at that time. So this kind of assembly production line is often used. But so far, many of these industries have moved to India and Southeast Asian countries.

另一方面, in developed countries, companies often choose automated assembly lines. The labor costs in these countries are high. 答案係肯定嘅, because many industries in these countries are high value-added, they can withstand the high investment costs of automation equipments.

因此, each company should consider whether to choose an automatic or a manual assembly line based on the return on investment of your own products. 另外, we must also consider whether there are corresponding technical personnel to operate and maintain equipments.

Although the modular assembly conveyor has a simple structure, it is always more complicated than a manual assembly line. 因此, it needs special technical personnel for operation and maintenance. The maintenance cost is relatively high.

(2) How to choose modular assembly line?

There are many factors that affect the choice of modular pallet conveyor assembly.

① What product to assemble?

首先, you need to inform the conveyor manufacturer of product information, such as product type, weight and size. Some products have special requirements for conveyor materials. 例如, medical equipment or pharmaceutical packaging has high requirements for sanitary conditions. 此時, we need to choose a special conveying medium, such as modular mattop chain.

此外, different product weights, different assembly line conveyors to choose. 如上所述, the timing belt conveyor is suitable for light-load products. The accumulating roller chain conveyor can transport heavy-duty products. In additon, different product sizes, different conveyor width to need. 此外, it will choose different workpiece pallets. 此外, products with too large sizes are not suitable for vertical circulation assembly lines.

② Determine the information of assembly conveyor system

首先, it needs to inform the conveyor shape & layout. Determine if the modular assembly line is straight, 循環 (horizontal or vertical), or other shapes. How about the conveying route? Where does it need to turn? These need to be confirmed based on the factory area and production process. 另外, sometimes in order to save floor space, we will choose a vertical circulation assembly line.

答案係肯定嘅, you need to tell the conveyor length. Some single assembly lines cannot be made too long. If the length of your assembly line conveyor exceed 15m, you’d better to choose free flow chain conveyor.

最後, it needs to know the conveyor speed. Do you need the workpiece pallet to move slowly or fast? This needs to be determined according to your production capacity requirements and process. The conveying speed of some products cannot be too fast.

③ What functions need to implement?

Different functions, different components or accessories to need. 例如, how about the positioning accuracy? Where do products need to stop, rotate, and turn? Whether need to install an emergency stop button? And do you need to install fixtures on the conveying medium? If you want to implement the counting function, then it needs to install the sensor.

If you customize the free chain conveyor, you’d better to confirm whether need the accesories, such as ESD workbench and lights.

④ The Plant Environment

That’s right. The plant environment will also affect the choice of assembly line conveyor. 例如, if the plant has explosion-proof requirements, so the selection of the motor is also very important. 同時, whether the workshop temperature is extremely high or extremely low? 另外, other factors, such as cleanliness, air humidity, and dryness will also affect the selection.

(3) How to choose the manual assembly line?

The choice method and step are similar to modular pallet assembly conveyor.

① Choose the type

There are many types of manual assembly lines. So you need to know what type you need. You can refer to the picture above. Whether it needs the ESD workbench and lights? Double-side or single-side? Straight or circular assembly line conveyor?

② Inform the product information

Different products, different materials to choose. 例如, the manual assembly line is popular in electronic industry. We know many electronic products have requirement for anti-static. So we need use the ESD conveyor belt and workbench. 此外, different weights, different motor to use.

③ Determine the conveyor sizes and details

How long do you need? And how about the height? The regular height is 750mm. And do you have requirements for the frame material and motor brand? 通常, the frame material is aluminum profile and painted steel tube. 此外, whether you need other accessories, such as exhaust pipe and electric fan?

總之, to choose a suitable assembly line conveyor system, you need to consider the situation of your own enterprise carefully. 同時, we must do a good job of technical communication with the manufacturer.